As a supplier of handheld shrink wrap machines, I've had numerous conversations with clients about the performance of these machines, especially in terms of energy efficiency. Energy efficiency is a critical factor in today's industrial landscape, not only for reducing operational costs but also for promoting sustainable practices. In this blog post, I'll delve into the performance of handheld shrink wrap machines from an energy - efficiency perspective.

How Handheld Shrink Wrap Machines Work

Before discussing energy efficiency, it's essential to understand how handheld shrink wrap machines operate. These machines typically use heat to shrink plastic wrap around products. The heat source can be an electric element or a propane burner, depending on the model. When the machine is activated, the heat is applied to the plastic film, causing it to contract and tightly conform to the shape of the item being wrapped.

Factors Affecting Energy Efficiency

- Heating Element Design: The design of the heating element plays a significant role in energy consumption. Modern handheld shrink wrap machines are equipped with advanced heating elements that are designed to heat up quickly and maintain a consistent temperature. This reduces the time the machine needs to be powered on, thus saving energy. For example, some machines use ceramic heating elements, which are known for their high - efficiency heat transfer and rapid heating capabilities.

- Thermostat Control: A well - calibrated thermostat is crucial for energy efficiency. It ensures that the machine doesn't overheat, which can waste energy. When the temperature reaches the set point, the thermostat automatically cuts off the power to the heating element. Once the temperature drops below the set level, the power is restored. This on - off cycle helps to maintain a stable temperature while minimizing energy consumption.

- Insulation: Good insulation in the machine can prevent heat loss. If a significant amount of heat escapes from the machine, more energy is required to maintain the desired temperature. High - quality handheld shrink wrap machines are often insulated with materials such as fiberglass or ceramic wool, which can effectively reduce heat dissipation.

Energy Efficiency in Different Types of Handheld Shrink Wrap Machines

- Electric Handheld Shrink Wrap Machines: Electric machines are popular due to their ease of use and relatively low maintenance. They are generally more energy - efficient than propane - powered ones in indoor settings. The energy consumption of an electric machine depends on its wattage. Lower - wattage machines consume less energy but may take longer to heat up and shrink the film. On the other hand, higher - wattage machines can work faster but use more electricity. However, many modern electric machines are designed to optimize the balance between speed and energy consumption.

- Propane - Powered Handheld Shrink Wrap Machines: Propane - powered machines are suitable for outdoor use or in areas where electricity is not readily available. The energy efficiency of these machines is related to the combustion efficiency of the propane burner. A well - tuned burner will burn propane more efficiently, producing more heat with less fuel. Additionally, some propane - powered machines are equipped with features like adjustable flame control, which allows the operator to use only the amount of fuel necessary for the job.

Comparison with Other Shrink Wrap Machines

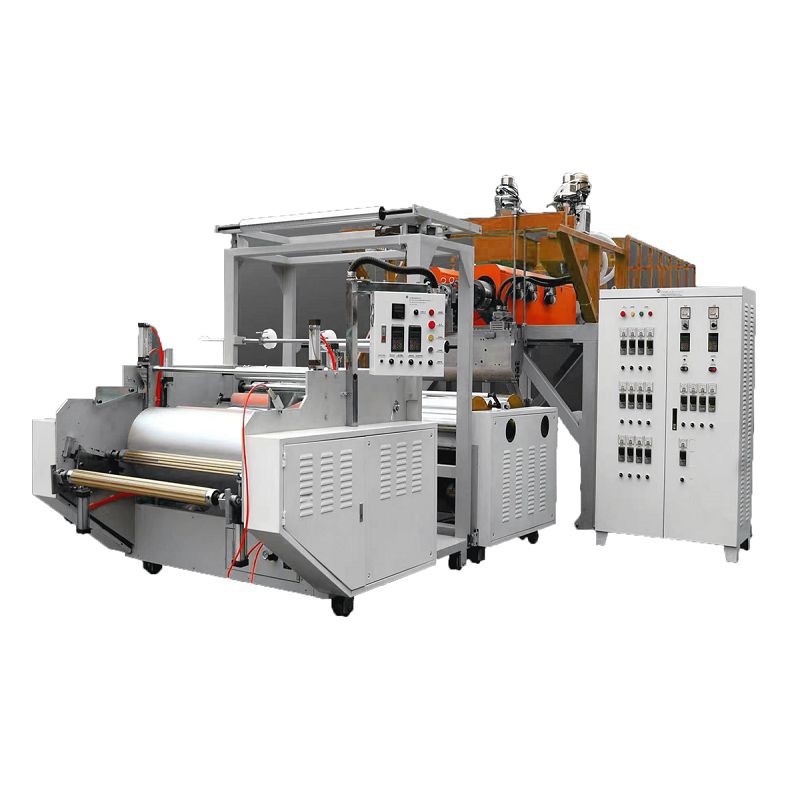

When compared to larger Industrial Stretch Wrap Machine and Automatic Shrink Wrap Machine For Pallets, handheld shrink wrap machines generally have lower energy consumption. Industrial and automatic machines are designed for high - volume production and often require more power to operate. However, they also offer higher productivity. Handheld machines, on the other hand, are more suitable for small - scale operations or for wrapping irregularly shaped items. They can be used on an as - needed basis, which can result in significant energy savings, especially for businesses with limited wrapping requirements.

Measuring Energy Efficiency

To accurately measure the energy efficiency of a handheld shrink wrap machine, several metrics can be used. One common metric is the energy consumption per unit of wrapped product. This can be calculated by dividing the total energy used (in kilowatt - hours for electric machines or liters of propane for propane - powered machines) by the number of products wrapped. Another important metric is the heat - up time. A machine that heats up quickly requires less energy overall, as it spends less time in the power - consuming pre - heating phase.

Real - World Performance and Case Studies

In real - world applications, the energy efficiency of handheld shrink wrap machines can have a substantial impact on a business's bottom line. For example, a small - scale e - commerce business that uses a handheld shrink wrap machine to package its products found that by switching to a more energy - efficient model, they were able to reduce their monthly energy costs by 20%. The new machine had a better - designed heating element and a more precise thermostat control, which allowed it to use less electricity while still providing excellent wrapping results.

The Importance of Energy Efficiency in the Long Run

Energy efficiency is not only about cost savings in the short term. It also has long - term environmental and economic benefits. By using less energy, businesses can reduce their carbon footprint, which is becoming increasingly important in today's environmentally conscious market. Additionally, as energy prices continue to rise, investing in energy - efficient equipment can provide a competitive advantage. Customers are also more likely to support businesses that demonstrate a commitment to sustainability.

Tips for Improving Energy Efficiency

- Proper Maintenance: Regular maintenance of the handheld shrink wrap machine is essential for optimal energy efficiency. This includes cleaning the heating element, checking the thermostat, and ensuring that the insulation is intact. A well - maintained machine will operate more efficiently and consume less energy.

- Correct Usage: Operators should be trained to use the machine correctly. This includes setting the appropriate temperature for the type of plastic film being used and avoiding over - heating. Using the machine only when necessary and turning it off when not in use can also save energy.

Conclusion

In conclusion, the energy efficiency of handheld shrink wrap machines is influenced by various factors, including the design of the heating element, thermostat control, and insulation. Different types of machines, such as electric and propane - powered ones, have their own energy - efficiency characteristics. Compared to larger industrial and automatic shrink wrap machines, handheld machines generally offer lower energy consumption, making them a great choice for small - scale operations. Measuring and improving energy efficiency can lead to significant cost savings and environmental benefits.

If you're interested in learning more about our range of Highlight Stretch Wrap Machine and other handheld shrink wrap machines, or if you'd like to discuss your specific wrapping needs and energy - efficiency requirements, please feel free to contact us. We're here to help you find the most suitable and energy - efficient solution for your business.

References

- "Handbook of Packaging Technology" by Wilmer A. Brown.

- Industry reports on energy - efficient packaging machinery.

- Case studies from businesses using handheld shrink wrap machines.