When it comes to the manufacturing of bottom seal bags, understanding the noise level of the bottom seal bag machine during operation is crucial for both the operators and the overall working environment. As a trusted supplier of bottom seal bag machines, we are committed to providing high - quality equipment while also ensuring that the operational conditions are as favorable as possible.

Understanding the Factors Affecting Noise Levels

The noise level of a bottom seal bag machine is influenced by several factors. Firstly, the mechanical components play a significant role. The motors, gears, and belts within the machine generate noise as they operate. For instance, a high - speed motor rotating at a rapid pace can produce a substantial amount of noise. The quality of these mechanical parts also matters. Inferior - quality gears may have uneven teeth, which can cause vibrations and increase the noise level during the meshing process.

Secondly, the working speed of the machine is another determinant. A bottom seal bag machine running at a high speed will generally produce more noise compared to one operating at a lower speed. This is because the faster the machine moves, the more intense the mechanical interactions are, leading to increased vibrations and sound emissions.

The design of the machine also affects the noise level. A well - designed bottom seal bag machine will have proper insulation and damping materials to reduce the transmission of noise. For example, using rubber gaskets between different parts can absorb some of the vibrations and thus lower the noise.

Measuring the Noise Level

To accurately measure the noise level of a bottom seal bag machine, we use professional sound - level meters. These meters are calibrated to measure the sound pressure level in decibels (dB). The measurement is usually taken at a specific distance from the machine, typically around 1 meter away from the main source of the noise.

In general, the noise level of a bottom seal bag machine during normal operation can range from 70 dB to 90 dB. A machine operating at a lower speed and with high - quality components may produce noise around 70 - 75 dB, which is similar to the noise level in a busy office environment. On the other hand, a high - speed machine with some mechanical wear and tear may reach up to 90 dB, which is comparable to the noise level of a lawnmower.

Impact of Noise on the Working Environment

Excessive noise in the workplace can have several negative impacts. For the operators, long - term exposure to high - level noise can lead to hearing loss. According to the World Health Organization, continuous exposure to noise levels above 85 dB can cause permanent damage to the ears. Moreover, high noise levels can also cause stress, fatigue, and reduced concentration among the workers, which may ultimately affect their productivity.

In addition, a noisy working environment can also violate local environmental regulations. Many regions have strict limits on the noise emissions from industrial equipment. As a responsible supplier, we ensure that our bottom seal bag machines comply with these regulations, so that our customers do not face any legal issues.

Our Solutions to Reduce Noise

We understand the importance of reducing the noise level of our bottom seal bag machines. That's why we have implemented several measures in our machine design and manufacturing process.

Firstly, we use high - quality mechanical components. Our motors are designed to operate smoothly and quietly, with advanced technology to reduce vibrations. The gears are precision - made to ensure a smooth meshing process, minimizing the noise generated during operation.

Secondly, we incorporate advanced insulation and damping materials in our machine design. These materials are strategically placed to absorb and dampen the vibrations, preventing them from being transmitted as noise. For example, we use special acoustic foams inside the machine cabinets to reduce the noise leakage.

We also offer the option of variable - speed control for our bottom seal bag machines. This allows the operators to adjust the working speed according to their needs. By running the machine at a lower speed when possible, the noise level can be significantly reduced.

Related Products

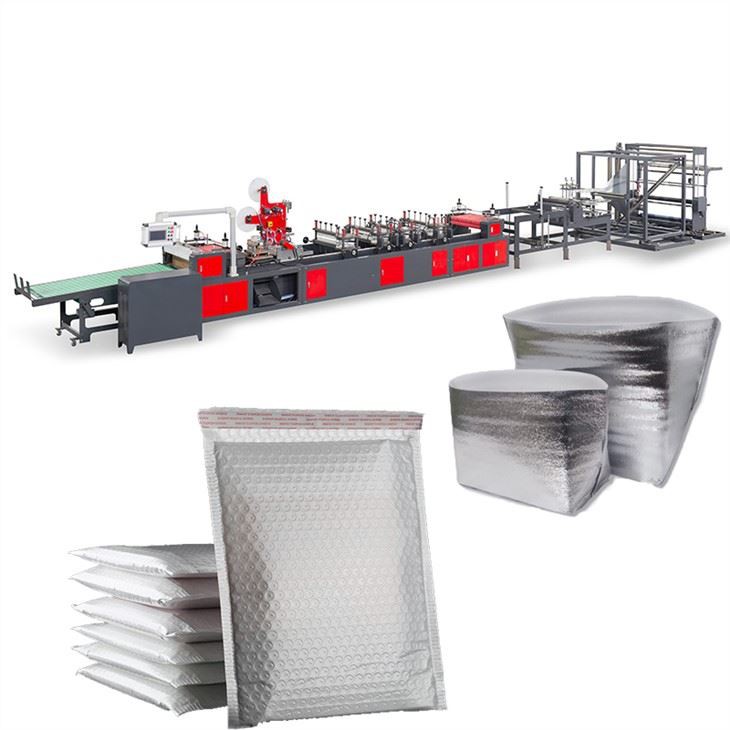

In addition to our bottom seal bag machines, we also offer a range of other bag - making machines. For example, our PP Nonwoven Soft Handle Making Machine is designed to produce high - quality non - woven bags with soft handles. This machine also features low - noise operation, ensuring a comfortable working environment.

Our Hdpe Bag Making Machine is another popular product. It is capable of producing HDPE bags with high efficiency and low noise. The advanced design of this machine ensures smooth operation and minimal noise emissions.

We also have a Side Sealing Bag Making Machine. This machine is suitable for making side - sealed bags with various sizes and materials. Similar to our other machines, it is engineered to operate quietly, providing a pleasant working experience for the operators.

Contact Us for Purchase and Negotiation

If you are interested in our bottom seal bag machines or any of our other products, we encourage you to contact us for purchase and negotiation. We have a professional sales team that can provide you with detailed product information, pricing, and after - sales service. Whether you are a small - scale business or a large - scale industrial enterprise, we can offer you the most suitable solutions for your bag - making needs.

References

- World Health Organization. "Occupational noise exposure." Fact sheet N°112.

- Machinery Noise Reduction Handbook. Industrial Press Inc.