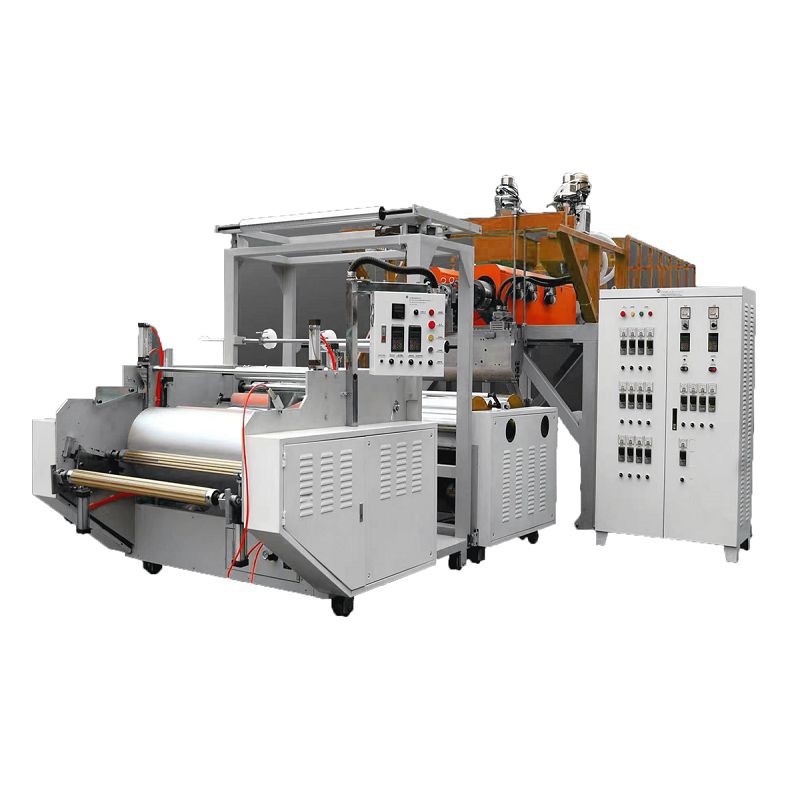

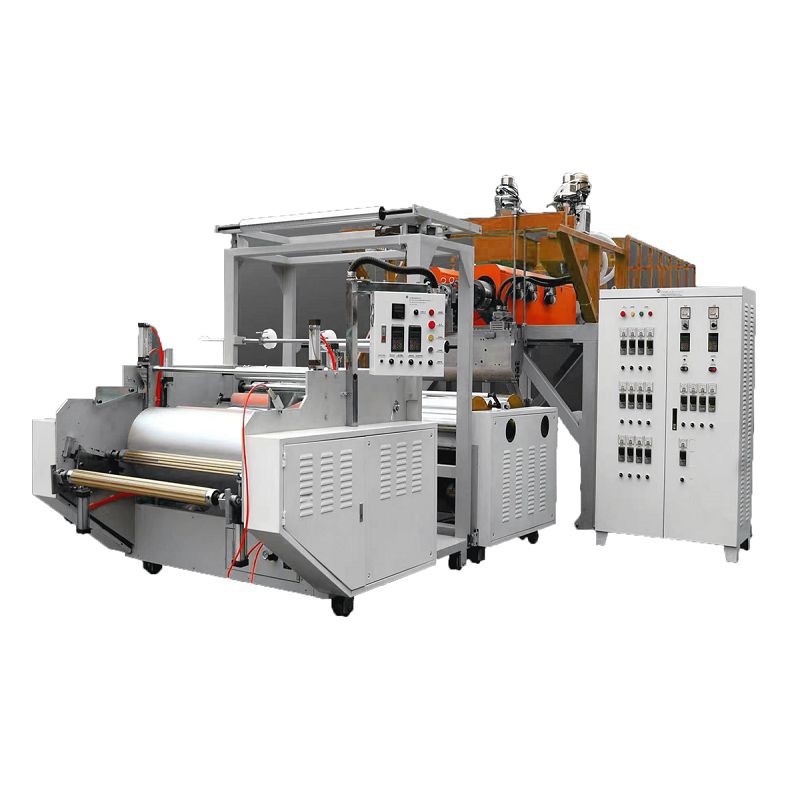

Industrial Stretch Wrap Machine

Why Choose Us?

Quality products: We have advanced production and testing equipment, and our products meet various standards.

Rich experience: We have years of industry experience and a team of experienced engineers and technicians to ensure consistent precision and high quality of our products.

Reliable service: Our team is committed to providing reliable and consistent service, ensuring that you receive high-quality products and customer support from us every time.

Professional team: The company is in possession of numbers of senior engineers and has abundant technique power, well conditioned equipment and technology comes to perfection.

What Is Industrial Stretch Wrap Machine

Industrial stretch wrap machine is mainly used for the production of unidirectional stretch polyethylene plastic film (stretch film, winding film) as well as cling film. It consists of three parts: The main machine, the auxiliary machine, and the electric control. It is designed to accommodate large rolls of stretch film and applies the film to the product by stretching it tightly as the product moves through the machine. This ensures that the product is securely wrapped and protected from damage during transit or storage.

Benefits of Industrial Stretch Wrap Machine

Precise wrapping adjustments

Industrial stretch wrap machines allows precise control of film properties like thickness, clarity, and strength.

Customizable

Industrial stretch wrap machines allow for the customizing of film width and thickness to meet the specific needs of customers.

Safety

Industrial stretch wrap machines are equipped with safety features like emergency stop buttons, safety guards, and safety interlocks to prevent accidents and ensure workers' safety.

Automated operations

Industrial stretch wrap machines are automated, making them efficient and fast in wrapping products. The machines are programmed to select and wrap the products according to the required specifications

Industrial stretch wrap machines are essential equipment in modern manufacturing and logistics operations for efficiently wrapping pallets or goods with stretch film to secure and protect them during transportation and storage. The working principle of an industrial stretch wrap machine can be broken down into several key steps:

1. Load Placement: The first step involves placing the pallet or goods to be wrapped onto the turntable of the machine. The turntable rotates to ensure even wrapping of the load.

2. Film Application:

The stretch film is fed from a roll mounted on a film carriage. The film carriage moves up and down as it wraps the film around the load, applying tension to stretch the film and secure it in place.

3. Tension Control:

Industrial stretch wrap machines are equipped with tension control mechanisms to adjust the amount of stretch applied to the film. This ensures that the film is securely wrapped around the load without causing damage.

4. Film Cutting and Sealing:

Once the wrapping process is complete, some machines have automatic cutting and sealing mechanisms that neatly cut the film from the roll and seal it in place, creating a tidy finish.

5. Control System:

Industrial stretch wrap machines are typically equipped with a control system that allows operators to set parameters such as wrapping speed, number of rotations, and tension levels. This ensures consistent and efficient wrapping of loads.

6.Safety Features:

To ensure safe operation, industrial stretch wrap machines are equipped with safety features such as emergency stop buttons, safety barriers, and sensors that detect obstructions or irregularities during the wrapping process.

7. Maintenance:

Regular maintenance of industrial stretch wrap machines is essential to ensure optimal performance and longevity. This includes cleaning components, lubricating moving parts, inspecting for wear and tear, and replacing any damaged parts.

Revolutionizing Packaging: The Application of Industrial Stretch Wrap Machines

In the modern era of manufacturing and logistics, efficiency and reliability in packaging have become paramount. As industries strive for optimization in every process, the advent of industrial stretch wrap machines has emerged as a game-changer in the packaging sector. These machines, designed to wrap stretch film around a loaded pallet or products, ensure stability, protection, and security during storage and transportation.

Enhancing Product Safety and Security

One of the primary applications of industrial stretch wrap machines is to enhance the safety and security of products during transit. By tightly wrapping products with a durable film, these machines protect goods from dust, moisture, and other environmental elements that could potentially damage them. Moreover, the robust wrapping ensures that products remain intact and do not shift during transportation, minimizing the risk of accidents or product loss.

Streamlining Packaging Processes

Industrial stretch wrap machines streamline packaging processes by automating what was once a manual and time-consuming task. With varying models equipped with advanced features like pre-stretch mechanisms, automatic film cutting, and adjustable wrap patterns, these machines can significantly increase packaging speed and consistency. This automation not only boosts productivity but also reduces labor costs and minimizes human error.

Versatility Across Industries

The versatility of industrial stretch wrap machines is evident in their application across a wide range of industries. From food and beverage to electronics, pharmaceuticals, and construction materials, these machines cater to diverse packaging needs. Whether it's wrapping pallets loaded with canned goods or securing large construction materials for shipment, industrial stretch wrap machines offer customizable solutions that can adapt to different product sizes and shapes.

Sustainability Considerations

In an era where environmental sustainability is increasingly important, industrial stretch wrap machines contribute by optimizing film usage. Advanced models are capable of stretching film up to 300% its original length before application, significantly reducing waste without compromising on protection or stability. This efficient use of materials not only lowers operational costs but also aligns with eco-friendly practices by minimizing plastic waste.

Enhancing Warehouse Efficiency

Beyond packaging efficiency, industrial stretch wrap machines play a crucial role in enhancing overall warehouse operations. By ensuring that goods are securely wrapped and ready for storage or shipment, these machines facilitate smoother warehouse workflows. Properly wrapped pallets are easier to stack and store efficiently, maximizing space utilization in warehouses.

Feature of Industrial Stretch Wrap Machine

The industrial stretch wrap machine can complete packaging tasks quickly and are much more efficient than manual packaging. At the same time, the machine can also ensure packaging quality and packaging speed, thereby improving production efficiency.

Our products can package items of different shapes and sizes, including irregularly shaped items. At the same time, the machine can also adjust parameters such as packaging strength and speed to adapt to different packaging needs.

Using this machine can avoid possible safety hazards in the manual packaging process, such as manual cutting. At the same time, the machine can also protect the packaged items from damage caused by improper packaging.

This machine consumes much less energy than manual packaging, and the machine also reduces the waste of packaging materials, thereby reducing the company's packaging costs.

The machine uses advanced technology and materials to ensure long-term stable operation and high-quality packaging results. At the same time, the machine is also easy to maintain and maintain, which can reduce the time and cost of interrupting production.

Stretch wrap and stretch film are two commonly used packaging materials in various industries. These materials offer excellent protection to goods during transportation and storage, preventing damage and ensuring product integrity. While stretch wrap and stretch film are often used interchangeably, there are subtle differences between them that are important to understand.

Stretch wrap, also known as pallet wrap or stretch film, is a highly stretchable plastic film used to secure loads on pallets. It is typically made from linear low-density polyethylene (LLDPE) or similar materials. Stretch wrap is available in various thicknesses, widths, and lengths, allowing for customization based on specific packaging requirements.

On the other hand, stretch film refers to a broader category of plastic films with elastic properties. While stretch wrap is a type of stretch film, not all stretch films are stretch wraps. Stretch films can be made from different types of plastics, including LLDPE, polyvinyl chloride (PVC), polypropylene (PP), or a combination of materials.

One of the key differences between stretch wrap and stretch film lies in their stretchability and cling characteristics.

Stretch wrap, as its name suggests, has exceptional stretchability. It can be stretched to a significant extent, typically up to 150-300% of its original length. This stretchability allows the film to conform tightly to the shape of the load, providing optimal stability and minimizing movement during transportation. Stretch wrap also possesses excellent cling properties, effectively sticking to itself to maintain load integrity.

In contrast, stretch films, although they may offer some level of stretchability, do not possess the same high stretchability as stretch wrap. The extent to which a stretch film can be stretched may vary based on its composition and thickness. Similarly, stretch films may exhibit different levels of cling, with some offering a higher cling property than others.

Key Features to Look for in an Industrial Stretch Wrap Machine

1. Pre-Stretch Capability

One of the most important features to consider is the pre-stretch capability of the machine. Pre-stretching is the process of stretching the wrap before applying it to the load. Machines with a high pre-stretch rate can significantly reduce film consumption by stretching the film up to 300% of its original length, leading to substantial savings in wrap costs and environmental impact.

2. Wrap Force Adjustment

The ability to adjust the wrap force is crucial for accommodating different load types and sizes. A good stretch wrap machine should allow you to easily adjust the tension of the wrap applied to the load, ensuring that it's tight enough to secure the load without damaging it.

3. Load Capacity

Consider the machine's load capacity, which includes weight capacity and size capacity (height and width). Ensure that the machine can handle your typical load sizes and weights. Overloading a machine or attempting to wrap loads that are too large can result in inefficient wrapping and potential damage to both the product and machine.

4. Wrap Cycle Customization

Look for machines that offer customizable wrap cycles. This feature allows you to program different wrapping patterns based on specific needs, such as reinforcing corners or adding extra wraps at certain points on a pallet, which can be particularly useful for irregularly shaped loads or products that require additional stabilization.

5. Ease of Use and Maintenance

A user-friendly interface is essential for efficient operation. Machines equipped with intuitive controls reduce training time and minimize operator errors. Additionally, consider machines designed with ease of maintenance in mind-quick access to common wear parts can significantly reduce downtime.

6. Safety Features

Safety should never be overlooked when selecting an industrial stretch wrap machine. Look for machines with built-in safety features such as emergency stop buttons, safety guards or curtains, and warning indicators or alarms for malfunctions.

7. Durability and Reliability

Given that these machines are a significant investment, their durability and reliability cannot be overstated. Opt for machines built with high-quality materials capable of withstanding heavy use over time. Additionally, consider manufacturers with good reputations who offer comprehensive warranties and responsive customer service.

How to Maintain Industrial Stretch Wrap Machine

Dust and debris can impair the performance of your machine and also the finish and quality of your packs. A regular wipe down of the equipment with a non-abrasive, clean and dry cloth should suffice. In particular, the sealing jaws on our machinery should be checked at the end of every shift to ensure no debris is caught in them. We also recommend using a dust cover when your machine is idle as a hassle-free solution to keeping it spotless.

Moisture can be damaging to mild steel machinery as it can cause rusting and corrosion. If you are wrapping liquids like chemicals or drinks, you would benefit considerably from upgrading to a stainless steel system, which can be easily washed down, for an increased lifespan.

Each company's servicing needs will be unique. Customers who run an intensive 24-hour wrapping operation will need more regular preventative maintenance than those who power up their equipment only seasonally or have low volumes. Liaise with our expert engineering team who can offer guidance on how regularly your equipment should be serviced depending on your usage. They will compile a personalised schedule with an arrangement to contact you prior to a service due date.

Making sure your operators know how to use the machine properly is the key to avoiding a lot of faults and potential damage. This is why comprehensive training is delivered free of charge by our engineering team at every machinery installation. To support your operators, we also recommend having a copy of the detailed machine manual readily available as a point of reference – this can be easily and safely stored inside the electrical cabinet. Electronic and paper copies of manuals are supplied with every machine.

Precautions for Operating the Industrial Stretch Wrap Machine

Always read and fully understand the operating manual provided by the manufacturer before using the machine.

Make sure all safety guards are in place and secured before operating the machine.

Do not exceed the maximum weight capacity of the machine.

Always wear appropriate personal protective equipment, such as gloves and safety glasses, when operating the machine.

Keep hands, loose clothing, and hair away from moving parts of the machine.

Do not try to adjust or repair the machine while it is in operation. Turn off the machine and disconnect it from power before making any adjustments.

Inspect the machine for any damaged or worn parts before each use and replace them as necessary.

Do not operate the machine in wet or damp conditions.

Keep the work area clear of obstacles and debris that could interfere with the operation of the machine.

Do not leave the machine unattended while it is in operation. Be vigilant and alert at all times.

7 Creative Ways to Use Your Industrial Stretch Wrap Machine

Protecting Furniture and Appliances

Wrapping furniture and appliances is the number one use for plastic stretch wrap, and for good reason. Since these items can't fit in a moving box, covering them entirely in a protective material is the next best solution. Some tips for wrapping your furniture and appliances:

● Clean and dry your items first.

● Remove extra pieces or parts (if applicable) to make wrapping easier.

● Leave some overlap so the wrap sticks to itself and stays in place.

● Wrap tightly so it stays in place during transport.

● Securing your furniture in plastic wrap alone is a solid way to protect against dust and debris, but for best protection, we recommend draping your item in a Furniture Pad/moving blanket first,his tactic is also helpful if you're wrapping a leather or wooden surface, as it will keep potential trapped moisture from damaging your belongings. Learn more about using moving blankets.

Bundling Long, Awkard Items

● Rakes bundled with plastic stretch wrap.

● Bundles Awkward Items.

● When it's time to pack the garage or shed, you may be wondering if there's an easy way to get those rakes, shovels, brooms, and other long, awkward items packed. Have we mentioned Mover's Wrap yet? Use a 5" roll to bundle these items together at the top and bottom of the handles. When bundled, they can be carried to the moving truck in one easy trip and won't shift in the truck once you're on the road. This doesn't apply only to lawn equipment. Any awkward non-fragile items, like curtain rods, couch cushions, stuffed animals, and electric cords can be bundled together using plastic stretch wrap.

Organizing Silverware

Silverware is another item that commonly gives movers trouble during the packing phase. You don't want your silverware set loosely cluttering the moving box, but you also don't want to waste time individually wrapping or bundling them together.It only takes minutes, so you'll have more time to pack glassware and dishware.

Rolling Up Rugs and Mats

● A rolled up rug with stretch plastic wrap

● Rolls Up Rugs & Mats

Quickly bundling large, awkwardly shaped items to make them easier to manage is a key benefit. Rugs and mats are another example of how this works.

Securing Liquids in Bottles

If you've built up a vast collection of cleaning supplies, shampoos, and other bottled liquids, you might be wondering how to move them without spilling. You can close the lid as tightly as you want, but extreme temperatures and altitude changes can affect the viscousness of the liquid and allow it leak out if the bottle topples.

Keeping Drawers Closed

● Plastic stretch wrap keeping drawers closed

● Keep Drawers Closed

● There's a lot of movement in the back of a moving truck once it gets going. If you load a dresser or cabinet without securing the drawers, you risk them flying open when you come to a stop or take a tight turn. Many people use tape to keep them shut, but that's tough to peel off later and it leaves behind a sticky mess on your furniture.

Covering Artwork and Wall Decor

Although we recommend going the extra mile when packing artwork for moving and using a proper box and packing kit, Mover's Wrap can be helpful here as well. Since the wrap is tear-resistant and residue-free, it makes a great cover for valuable artwork and framed wall decor. Use it to keep glass frames from cracking or shattering. Or use it as an extra layer of protection before placing the frame in a box.

Jiangxi Zhetuo Machinery Co., LTD., located in Jinbu Town, Yugan County, Shangrao City, Jiangxi Province, was established in September 2012. Is an annual output value of more than 100 million yuan of packaging machinery technology manufacturing enterprises.

Our Certificate

FAQ

Q: What is stretch wrap good for?

Q: What are the benefits of pallet wrapping machine?

Q: What is an industrial stretch wrap machine?

Q: How does an industrial stretch wrap machine work?

Q: What are the key components of an industrial stretch wrap machine?

Q: What types of industrial stretch wrap machines are available?

Q: What are the benefits of using an industrial stretch wrap machine?

Q: Can industrial stretch wrap machines handle different pallet sizes?

Q: What is pre-stretching, and why is it important?

Q: How do you choose the right type of stretch film for an industrial stretch wrap machine?

Q: Are there any safety concerns with using these machines?

Q: How does automation level affect the choice of an industrial stretch wrap machine?

Q: What maintenance is required for these machines?

Q: Can these machines be integrated into existing packaging lines?

Q: What factors should be considered when installing an industrial stretch wrap machine?

Q: How does climate or environment affect machine operation or choice?

Q: What material is stretch wrap made of?

Q: How strong is stretch wrap?

Q: How long does stretch wrap last?

Q: Is stretch wrap UV resistant?

Hot Tags: industrial stretch wrap machine, China industrial stretch wrap machine manufacturers, suppliers

You Might Also Like

Send Inquiry