In the dynamic world of packaging, polypropylene (PP) bags have emerged as a popular choice due to their versatility, durability, and cost - effectiveness. As a leading Pp Bag Machine supplier, I am often asked about the quality of bags produced by our machines. In this blog, I will delve into the various aspects that define the quality of PP bags made by our Pp Bag Machines.

Material Quality

The quality of PP bags starts with the raw material. Polypropylene is a thermoplastic polymer known for its high strength - to - weight ratio, chemical resistance, and excellent processability. Our Pp Bag Machines are designed to work with high - grade polypropylene resins. These resins are carefully selected for their purity, melt flow index, and molecular weight distribution.

A proper melt flow index is crucial as it determines how easily the resin can be melted and extruded during the bag - making process. If the melt flow index is too low, the resin may not flow smoothly through the machine, leading to uneven thickness and potential defects in the bags. On the other hand, if it is too high, the bags may lack the necessary strength. Our machines are calibrated to work optimally with the selected resins, ensuring that the bags have consistent quality in terms of material composition.

Structural Integrity

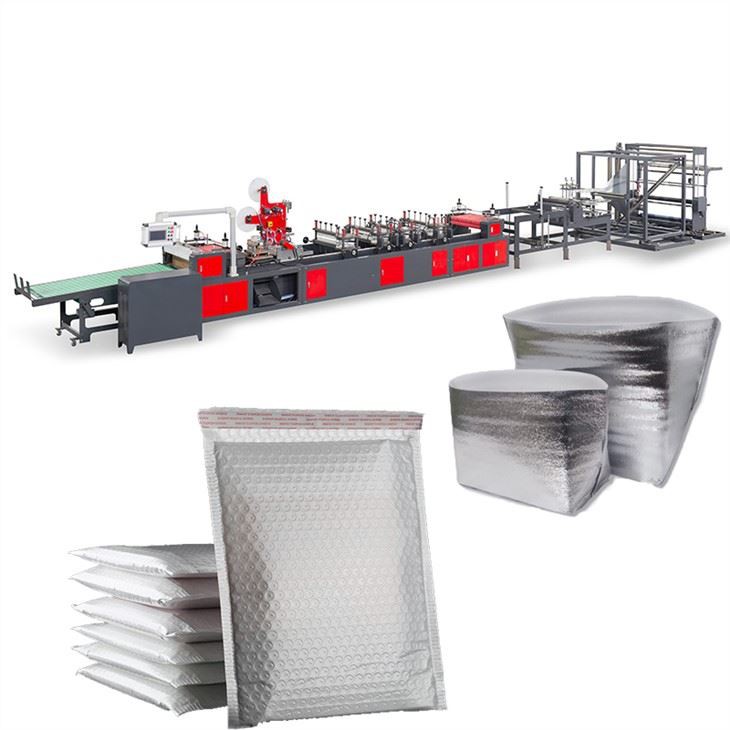

One of the key indicators of a high - quality PP bag is its structural integrity. Our Pp Bag Machines are equipped with advanced technology to ensure proper sealing and bonding of the bag. For example, in the case of side - sealed bags, our Side Sealing Bag Making Machine creates strong and uniform seals. The sealing process is carefully controlled to prevent leaks, which is especially important for bags that are used to package liquids or fine powders.

The thickness of the bag also plays a vital role in its structural integrity. Our machines can produce bags with a wide range of thicknesses, from thin and lightweight bags for packaging small items to thicker, more robust bags for heavy - duty applications. The thickness is precisely controlled through the extrusion process, ensuring that each bag meets the specified requirements.

Print Quality

In today's competitive market, branding and product information on bags are essential. Our Pp Bag Machines can produce bags with high - quality printing. Whether it is simple text or complex graphics, our machines are capable of achieving sharp and clear prints. The printing process uses advanced inks and printing techniques, such as flexography or gravure printing.

Flexography is a popular choice for PP bag printing as it is cost - effective and can produce high - volume prints with good quality. Our machines are designed to handle different types of inks, including water - based inks, which are more environmentally friendly. The registration of the print is also carefully controlled to ensure that the graphics and text are accurately placed on the bags.

Dimension Accuracy

Accurate dimensions are crucial for PP bags, especially when they are used in automated packaging systems. Our Pp Bag Machines are engineered to produce bags with precise dimensions. The cutting and folding mechanisms are highly accurate, ensuring that each bag has the correct length, width, and height.

For example, if a bag is designed to fit a specific product or a packaging line, even a small deviation in dimensions can cause problems. Our machines use advanced sensors and control systems to monitor and adjust the production process in real - time, ensuring that the bags meet the required dimensional tolerances.

Environmental Considerations

In recent years, environmental concerns have become increasingly important in the packaging industry. Our Pp Bag Machines are designed to produce bags that are more environmentally friendly. Polypropylene is a recyclable material, and our machines can produce bags that are easily recyclable.

In addition, we also offer options for producing biodegradable or compostable PP bags. These bags are made from special blends of polypropylene and other biodegradable polymers. Our Nonwoven Fabric Sheet Cutting Machine can be used in the production of nonwoven PP bags, which are not only strong and durable but also more sustainable compared to traditional plastic bags.

Production Efficiency and Consistency

Another aspect of the quality of bags produced by our Pp Bag Machines is the production efficiency and consistency. Our machines are designed for high - speed production without compromising on quality. They can produce a large number of bags in a short period, which is essential for meeting the demands of large - scale manufacturers.

Moreover, the machines are built with high - quality components and advanced control systems to ensure consistent production. Each bag produced is of the same high quality, regardless of the production volume. This consistency is crucial for maintaining the reputation of our customers' products and brands.

Customization Options

We understand that different customers have different requirements for their PP bags. Our Pp Bag Machines offer a wide range of customization options. We can produce bags in different shapes, such as square, rectangular, or even custom - designed shapes. The bags can also be customized with different handles, zippers, or other features.

For example, if a customer needs a bag with a special closure mechanism for easy opening and closing, our machines can be adapted to produce such bags. Our Side Sealing Bag Making Machine can be configured to create bags with different side - sealing styles, depending on the customer's needs.

Conclusion

In conclusion, the quality of bags produced by our Pp Bag Machines is defined by multiple factors, including material quality, structural integrity, print quality, dimension accuracy, environmental considerations, production efficiency, and customization options. As a Pp Bag Machine supplier, we are committed to providing our customers with machines that can produce high - quality PP bags that meet their specific requirements.

If you are in the market for Pp Bag Machines or are interested in learning more about the quality of bags our machines can produce, we invite you to contact us for a detailed discussion. We are happy to assist you in finding the right solution for your packaging needs.

References

- Packaging Technology Handbook, John Wiley & Sons

- Polypropylene: Structure, Blends and Composites, Rapra Technology Limited