As a seasoned supplier of handheld stretch wrappers, I've witnessed firsthand the diverse experiences our customers have with these essential tools. Handheld stretch wrappers are invaluable in various industries, offering flexibility and efficiency in packaging operations. However, like any piece of equipment, they come with their own set of common problems. In this blog, I'll delve into these issues, providing insights and solutions to help you get the most out of your handheld stretch wrapper.

Inconsistent Stretch Ratio

One of the most prevalent problems with handheld stretch wrappers is achieving an inconsistent stretch ratio. The stretch ratio refers to the amount the film is stretched during the wrapping process. An inconsistent stretch ratio can lead to uneven tension on the load, causing some areas to be over - wrapped while others are under - wrapped. This not only affects the stability of the load but also wastes stretch film.

The root causes of inconsistent stretch ratio can be multi - fold. Firstly, the quality of the Machine Stretch Film plays a crucial role. If the film has variations in its thickness or elasticity, it will stretch differently in different parts of the roll. Secondly, the operator's technique can also have a significant impact. Uneven pulling speed or pressure on the wrapper can result in inconsistent stretching.

To address this issue, it's essential to use high - quality stretch film that has been tested for uniform thickness and elasticity. Additionally, providing proper training to operators on how to maintain a consistent pulling speed and pressure can go a long way in ensuring a more uniform stretch ratio.

Film Breakage

Film breakage is another common headache when using handheld stretch wrappers. It can occur during the wrapping process, interrupting the workflow and causing delays. There are several reasons why film breakage might happen.

One reason is excessive stretching. If the wrapper is set to stretch the film beyond its capacity, it will eventually break. This can be due to incorrect settings on the wrapper or using a film that is not suitable for high - stretch applications. Another cause could be sharp edges on the load. If the product being wrapped has sharp corners or edges, they can cut through the film, leading to breakage.

To prevent film breakage, it's important to select the right film for the job. Different types of Machine Stretch Film have different stretch capabilities, so choose one that can handle the required stretch ratio without breaking. Also, ensure that the load is properly prepared. You can use corner protectors or smooth out any sharp edges before wrapping.

Difficulty in Film Loading

Loading the stretch film onto the handheld wrapper can be a frustrating experience for many operators. It often involves threading the film through various guides and rollers, and if not done correctly, it can lead to jams and misalignments.

The design of the wrapper itself can contribute to this problem. Some older models may have complex or poorly designed film loading mechanisms that are difficult to understand and operate. Additionally, the film core size and compatibility can also cause issues. If the film core does not fit properly on the wrapper's spindle, it can make loading and unwinding the film a challenge.

To simplify film loading, look for handheld stretch wrappers with user - friendly loading mechanisms. Newer models often feature clear instructions and easy - to - use guides that make the process much smoother. Also, ensure that the film core size is compatible with your wrapper.

Poor Wrapper Mobility

Handheld stretch wrappers are designed to be portable, but sometimes they can suffer from poor mobility. This can make it difficult for operators to move around the load and wrap it efficiently.

One reason for poor mobility could be the weight of the wrapper. If the wrapper is too heavy, it can tire out the operator quickly, especially when wrapping large or multiple loads. Another factor is the design of the handle. A poorly designed handle can cause discomfort and make it difficult to grip and maneuver the wrapper.

To improve mobility, choose a lightweight handheld stretch wrapper that is ergonomically designed. Look for models with comfortable handles that reduce fatigue and allow for easy gripping and movement.

Lack of Tension Control

Proper tension control is crucial for effective wrapping. Without it, the load may not be secured tightly enough, leading to shifting and damage during transit. Some handheld stretch wrappers may lack precise tension control mechanisms, resulting in either too much or too little tension on the film.

This can be due to a faulty tension adjustment system or a lack of calibration. If the tension adjustment knob or lever is not working correctly, it will be impossible to set the desired tension. Additionally, if the wrapper has not been calibrated regularly, the tension readings may be inaccurate.

To ensure proper tension control, invest in a handheld stretch wrapper with a reliable tension adjustment system. Regularly calibrate the wrapper to maintain accurate tension settings. You can also train operators on how to adjust the tension according to the specific requirements of each load.

Wear and Tear of Components

Over time, the components of a handheld stretch wrapper can experience wear and tear. This can include the rollers, gears, and handles. Wear and tear can affect the performance of the wrapper, leading to issues such as inconsistent stretching, film breakage, and poor mobility.

The frequency of use and the operating conditions play a significant role in the rate of wear and tear. If the wrapper is used frequently in harsh environments, such as dusty or wet conditions, the components will degrade more quickly.

To minimize wear and tear, it's important to perform regular maintenance on the wrapper. This includes cleaning the components, lubricating the moving parts, and replacing any worn - out parts promptly. Following the manufacturer's maintenance schedule can help extend the lifespan of the wrapper.

Compatibility Issues with Stretch Films

Not all handheld stretch wrappers are compatible with all types of stretch films. Some wrappers may be designed to work best with a specific brand or type of Machine Stretch Film. Using an incompatible film can lead to problems such as poor stretching, film breakage, and difficulty in loading.

This can be a challenge, especially if you want to switch to a different type of film for cost - saving or performance reasons. Before making a change, it's important to check the compatibility of the new film with your wrapper. You can consult the manufacturer's guidelines or contact their customer support for advice.

Limited Battery Life (for Electric Wrappers)

If you're using an electric handheld stretch wrapper, limited battery life can be a major problem. It can disrupt your workflow, especially if you're in the middle of a large wrapping job.

The battery life can be affected by several factors. The age of the battery is one of them. Over time, the battery's capacity will decrease, resulting in shorter run times. The power consumption of the wrapper also plays a role. If the wrapper has a high - power motor or additional features, it will drain the battery more quickly.

To address this issue, keep spare batteries on hand. You can also invest in high - capacity batteries that can provide longer run times. Additionally, follow the manufacturer's instructions on battery charging and storage to maximize its lifespan.

Noise and Vibration

Some handheld stretch wrappers can produce excessive noise and vibration during operation. This can be a nuisance for operators and may even pose a health risk in the long run.

Excessive noise and vibration can be caused by a variety of factors. Loose components, worn - out bearings, or an unbalanced motor can all contribute to this problem.

To reduce noise and vibration, regularly inspect the wrapper for loose parts and tighten them as needed. Replace any worn - out bearings or other components that may be causing the issue. You can also look for models that are designed to minimize noise and vibration.

Conclusion

Handheld stretch wrappers are indispensable tools in many industries, but they do come with their share of common problems. By being aware of these issues and taking proactive steps to address them, you can ensure that your handheld stretch wrapper operates efficiently and effectively.

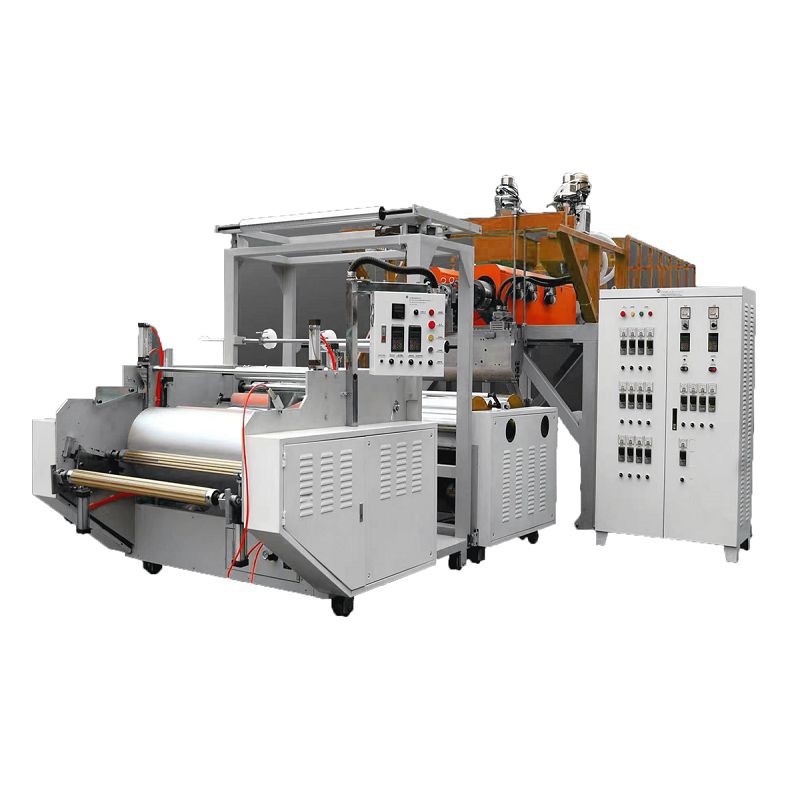

As a supplier of handheld stretch wrappers, we are committed to providing high - quality products and excellent customer service. If you're experiencing any of the problems mentioned above or are looking for a reliable handheld stretch wrapper, we encourage you to contact us for a detailed discussion. Our team of experts can help you choose the right wrapper for your specific needs and provide support on installation, maintenance, and troubleshooting. Whether you're interested in our Highlight Stretch Wrap Machine or 1500mm Full Automatic Stretch Film Machine, we're here to assist you. Don't hesitate to reach out and start a conversation about your packaging requirements.

References

- Industry standards and guidelines for handheld stretch wrappers

- Manufacturer's manuals and documentation for various handheld stretch wrapper models

- Research studies on the performance and common issues of stretch film and stretch wrappers