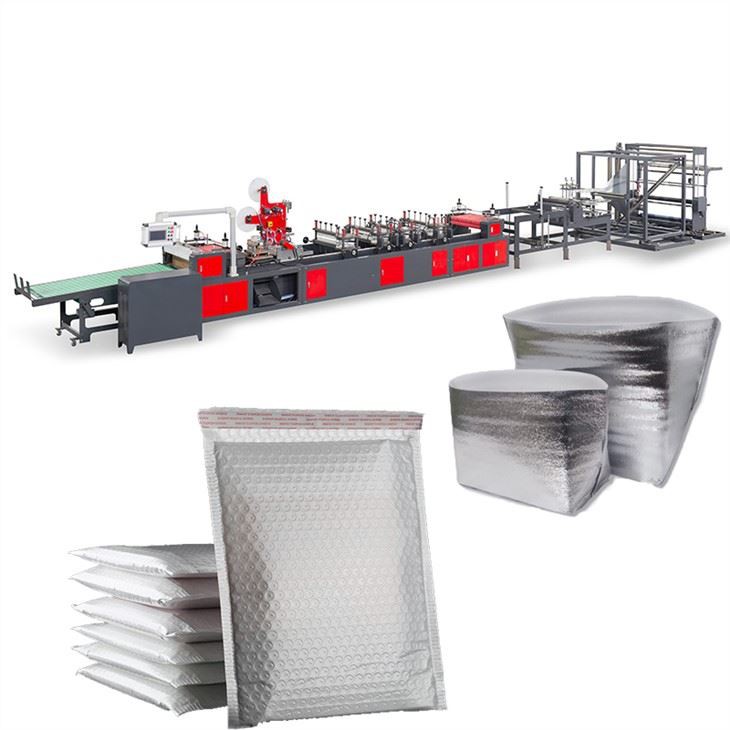

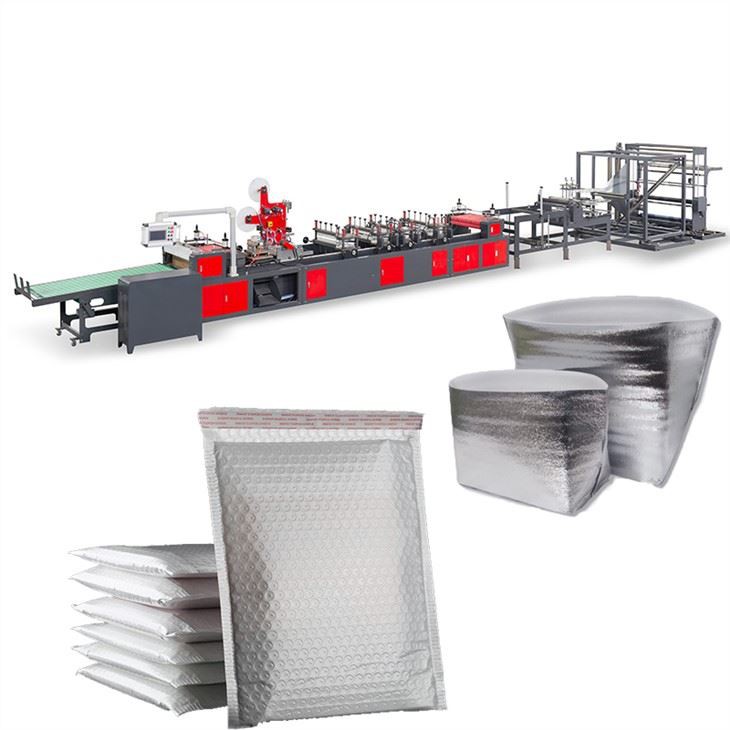

Side Sealing Bag Making Machine

Why Choose Us?

Quality products: We have advanced production and testing equipment, and our products meet various standards.

Rich experience: We have years of industry experience and a team of experienced engineers and technicians to ensure consistent precision and high quality of our products.

Reliable service: Our team is committed to providing reliable and consistent service, ensuring that you receive high-quality products and customer support from us every time.

Professional team: The company is in possession of numbers of senior engineers and has abundant technique power, well conditioned equipment and technology comes to perfection.

What Is Side Sealing Bag Making Machine

A side sealing bag making machine is a type of equipment used in the packaging industry to produce plastic bags with a side seal. These machines are commonly used in the production of various types of bags, such as shopping bags, garbage bags, food packaging bags, and more.

Customization

Many side sealing bag making machine allow for customization of seal patterns and designs, which can be a branding opportunity for businesses. This feature helps create a unique and recognizable packaging identity.

Environmentally friendly

Some side sealing bag making machine use eco-friendly materials and methods. By reducing the need for excess packaging, they contribute to a more supportable approach to product packaging.

Versatility

Side sealing bag making machine can be used for a wide range of products, from food items to pharmaceuticals, electronics, and more. They adapt to various packaging materials, including plastic, aluminum, and paper.

Increased productivity

Automated side sealing bag making machine can significantly increase production rates. They can seal numerous packages in a short amount of time, reducing labor costs and time spent on manual sealing.

Consistency

Side sealing bag making machine offer a high level of consistency in seal quality. This consistency is essential to ensure the reliability and safety of packaged products.

Electric motors are commonly used in a wide range of applications, including side sealing bag making machines. A side sealing bag making machine is a device that is used to seal the top of a cup or container, typically made of plastic or paper. These machines are commonly used in the food and beverage industry to package products such as drinks, soups, and sauces. The process of sealing a cup involves heating a film or lid and then pressing it onto the top of the cup to create a tight seal.

There are several types of electric motors that are used in side sealing bag making machines, including ac motors and dc motors. Ac motors are powered by alternating current and are commonly used in industrial applications. They are typically more efficient and have a longer lifespan than dc motors. Dc motors, on the other hand, are powered by direct current and are commonly used in smaller, less demanding applications.

One of the most common types of electric motors used in side sealing bag making machines is the stepper motor. A stepper motor is a type of motor that moves in small, precise increments, allowing for precise control over the movement of the machine. This is particularly useful in side sealing bag making machines, as the machine needs to be able to seal the top of the cup with precision in order to create a tight seal.

Another type of electric motor that is commonly used in side sealing bag making machines is the servo motor. A servo motor is a type of motor that is able to rotate to a specific angle, and is often used in applications that require precise control. This is also useful in side sealing bag making machines, as the machine needs to be able to rotate the sealing head to the correct position in order to seal the top of the cup.

One of the main benefits of using an electric motor in a side sealing bag making machine is that it provides a high level of precision and control. Electric motors are able to move in small, precise increments, which allows for a tight seal to be created on the top of the cup. Additionally, electric motors are able to rotate to a specific angle, which allows for the sealing head to be positioned correctly.

Another benefit of using an electric motor in a side sealing bag making machine is that it is energy efficient. Electric motors are able to convert electrical energy into mechanical energy with a high degree of efficiency, which reduces the amount of energy that is wasted during the sealing process. This can result in significant cost savings for the user over time.

Plastic Bag Making Machines Types and Uses

Bottom seal bag making machine

Makes bottom sealed plastic carrier bags using tubular rolls of different sizes. They are used to produce standard bottom seal bags, handle punch bags, multi-hole punch bags, and twin sealed handle punch bags, using the corresponding dies to shape the handles of the bags.

Depending on the length, width and application of the bag, flying knife bottom seal bag making machines can also be used.In such machines, the sealing of the film is done by a wire seal system which provides a very strong seal, while the cutting is done through a mechanically driven rotary flying knife.

Side seal bag making machine

Is used to create side sealed plastic bags by converting either a lay flat sheet or a tubular roll of PE or PP material. Depending on the type of handle and use of the plastic bag, you can choose from:

● Automatic patch handle bag making machine

● Automatic soft loop handle bag making machine

● Side seal zipper bag making machine

● Automatic soft loop & patch handle bag machine

Soft loop handle bag machine

These machines are used for attaching either loop or patch handles to side and bottom sealed plastic carrier bags. In case of loop handles, plastic strips are welded to the inside of the bag, allowing the complete volume of the bag to be utilized.

Whereas, patch handle bag making machines include a glued on patch around the die-cut handle to provide extra strength. Such bags are most commonly used in furniture and clothing stores that retail in bulkier items. There are four variants of such machines, namely:

●Semi automatic soft loop handle bag making machine

● Automatic patch handle bag making machine

● Automatic soft loop handle bag making machine

● Automatic soft loop & patch handle bag machine

T-shirt bag making machine

Produces your everyday single use shopping bag or grocery bag using hdpe since they are mass produced at a very low cost. Such machines first cut and seal the plastic film using a hot knife, after which the bags are forwarded to the punching station where he handle punching is done to receive the finished products.

How Does Side Sealing Bag Making Machine Work

Side sealing bag making machine is a type of equipment that is used to seal various types of bags, such as plastic bags, paper bags, and foil bags. The machine works by applying heat to the opening of the bag, which melts the material and creates a seal.

The specific operation of a side sealing bag making machine may vary depending on the type and model, but generally, the machine works as follows:

● The bag is placed in the sealing area of the machine. The sealing area is usually a flat surface or a clamp that holds the bag in place.

● The operator adjusts the temperature and pressure settings on the machine according to the type of bag being sealed.

● The machine applies heat to the opening of the bag using a heating element, which melts the material and creates a seal.

● Depending on the type of machine, the sealing process may be automatic or manual. Automatic machines use sensors to detect when the seal is complete and then release the bag, while manual machines require the operator to manually release the bag after the seal is complete.

● Once the bag is sealed, it can be removed from the machine and is ready for use.

Features of Side Sealing Bag Making Machine

Side sealing bag making have become increasingly popular due to the shift towards eco-friendliness and the reduction of plastic usage. Side sealing bag making machines have evolved to meet this growing demand. Some notable advancements in this domain include the following:

Automation:

Modern side sealing bag making machines are highly automated because of which they reduce the need for manual labour. They can handle various paper types and produce bags with consistent quality and high efficiency.

Customization:

These machines offer increased flexibility, enabling the production of bags in various shapes and sizes. Custom prints, logos, and designs are easily achievable, catering to the branding needs of businesses.

Sustainable materials:

Side sealing bag making machines are capable of using sustainable and recyclable materials, supporting environmentally responsible bag production. Additionally, these machines are designed to minimize waste and optimize material usage.

High-speed production

Advancements in mechanical and electronic components have allowed for higher production speeds, reducing lead times and improving overall productivity.

Smart controls

Smart sensors and control systems are integrated into modern machines. These systems monitor and adjust various parameters in real-time, ensuring consistent quality and reducing errors in the production process.

Energy efficiency

Many side sealing bag making machines are embedded with energy-saving components and systems, which help reduce operational costs and environmental impact.

Remote monitoring

Remote monitoring and control capabilities enable operators to oversee production from a distance and make real-time adjustments as needed. This feature has proven to be especially beneficial for managing large-scale production facilities.

Process of Manufacturing of Side Sealing Bag

Various specialised attachments are used, but the overall process remains almost the same. The blending of materials, extrusion, printing and finishing are vital steps. Below is a simple description of the overall process of manufacturing:

Blending of material: The polyethylene/polypropylene resin is mixed with some important additives. They are:

● EPI – it is included to make the bag degradable.

● Masterbatch for making the colored film. It may be black, yellow, white, blue or red.

● UVI, also known as an ultraviolet inhibitor is used for protecting the bag from uv radiation.

● Anti-static is used for preventing the sticking of plastic layers with each other. It enables easy opening of bags.

Extrusion: Once the process of blending gets complete, the mixture is extruded through an annulor die. The airstream will help in blowing the bubble up followed by cooling down the plastic to make various types of plastic films.

This important step will affect the strength, thickness, consistency and transparency of the film.

Printin: Once films are made in roll form, further processing of printing if required can take place on printing machine. Based on printing designs along with several colors, the exporter in India and the USA provides prints to the side sealing bag . It may be either flexo or gravure.

Bag making: Giving a finishing touch – now comes the touch of providing a finishing touch. Cutting along with sealing and folding are three important steps involved. The method may vary on the types of bags.

How Side Sealing Bag Making Machines Are Revolutionizing Packaging Industry

Side sealing bag making machines are revolutionizing the packaging industry in several ways:

These machines are capable of producing bags at a much faster rate compared to manual methods. This not only saves time but also increases productivity, allowing manufacturers to meet the growing demand for packaging materials.

By automating the bag making process, companies can significantly reduce labor costs and minimize wastage of materials. This helps in increasing profitability and staying competitive in the market.

Side sealing bag making machines offer a wide range of customization options such as size, shape, color, and design. This allows companies to create unique and eye-catching packaging solutions that can help in branding and marketing their products effectively.

These machines ensure uniformity in the production of bags, resulting in consistent quality and appearance. This is essential for maintaining the integrity of the products being packaged and building trust among consumers.

Many side sealing bag making machines are designed to be eco-friendly by using biodegradable materials and minimizing waste. This aligns with the growing consumer demand for sustainable packaging solutions.

Maintenance Tips for Side Sealing Bag Making Machine

Maintenance Tips for Side Sealing Bag Making Machine

1. Daily maintenance checklist

Performing daily maintenance checks is essential to keep your sealing machine running smoothly.

Here are some daily maintenance tasks to include in your checklist:

● Check the temperature and pressure settings to ensure they are within the recommended range.

Inspect the sealing jaws for damage or wear and tear.

● Clean the sealing jaws with a soft cloth and a non-abrasive cleaning solution.

● Check the supply of packaging materials, such as film or bags, to ensure they are not running low.

● Clear any debris or packaging material from the machine to prevent jams.

● By performing these simple checks every day, you can catch potential issues before they become major problems.

2. Weekly maintenance checklist

In addition to daily checks, there are some weekly maintenance tasks that you should include in your checklist.

Weekly maintenance tasks include:

● Lubricate moving parts, with a grade lubricant.

● Clean the machine's exterior with a soft cloth and a mild detergent solution.

● Inspect the electrical connections and wires for damage or wear.

● Verify the accuracy of the temperature and pressure settings with a thermometer and pressure gauge.

● By performing these weekly checks, you can keep your machine running smoothly and avoid unexpected breakdowns.

3. Monthly maintenance checklist

Finally, performing monthly maintenance tasks will keep your sealing machine in top condition.

Monthly maintenance tasks include:

● Replace any worn or damaged parts, such as the sealing jaws or heating elements.

● Deep clean the machine, including the interior components and any hard-to-reach areas.

● Calibrate the temperature and pressure settings to ensure they are accurate.

● Check the machine's manual for any additional maintenance requirements or recommendations.

● Performing these monthly checks can help you catch any issues before they become major problems and keep your machine running smoothly for years to come.

How Is the Quality of the Bags Ensured by a Side Sealing Bag Making Machine

The quality of the bags produced by a side sealing bag making machine is ensured through various mechanisms built into the machine:

1. Accurate Cutting: The side sealing bag making machine is equipped with precision cutting blades that accurately cut the film roll to the desired size. This ensures that the bags are of the correct size and shape.

2. Tension Control: The machine has tension control features that ensure the film roll is uniformly tensioned, which prevents wrinkles and creases in the bags. This enhances the quality of the bags.

3. Temperature Control: The heat sealing element of the machine uses temperature control to ensure that the bag is properly sealed. It prevents overheating, which can cause the bags to melt or underheat, which can cause the bag to get unsealed.

4. Automated Controls: The machine has automated controls that monitor and adjust various parameters, including temperature, feeding, cutting, and sealing, to ensure that the bags meet the required quality standards.

5. Inspection systems: The side sealing bag making machine includes inspection systems to check for defects such as wrinkles, creases, or holes in the bags. Any defective bags are automatically rejected, thereby ensuring only quality bags reach the end-user.

Since the late 19th century, when the first plastic bags were invented, the category of "side sealing machines" has consistently held the largest market share within the global "plastic bag making machine" industry. This dominance can be attributed to the continued reliance on plastic bags, particularly in packaging, where they remain a convenient and cost-effective solution. Leading the pack in technological advancements in this field are countries like Germany, the United States, Taiwan, and Turkey.

The evolution of side sealing bag making machines has been marked by significant advancements in technology, efficiency, and versatility.

In the early stages, side sealing bag making machines were basic in design and functionality. They were typically mechanical devices that relied on basic principles of heat sealing to create bags. These early models were often limited in terms of production speed, bag size, and material options.

As electronics became more advanced, side sealing bag making machines began to incorporate electronic controls and automation features. This allowed for more precise control over sealing temperatures, bag sizes, and production speeds. Electronic automation also made it easier to adjust and maintain the machines.

With the advent of microprocessor controls and servo motors, side sealing bag making machines became even more precise and efficient. These advanced control systems allowed for real-time monitoring and adjustment of machine parameters, ensuring consistent bag quality and production rates.

Modern side sealing bag making machines are designed to handle a wide range of materials and bag sizes. They often come with interchangeable sealing bars and cutting units, allowing for easy customization to meet specific production needs. Some machines even offer additional features like notching, perforating, and printing capabilities.

As environmental and worker safety concerns have grown, side sealing bag making machines have evolved to incorporate sustainable design practices and safety features. This includes energy-efficient components, waste reduction features, and ergonomic designs to minimize operator fatigue and injury.

Precautions for Operating Side Sealing Bag Making Machine

Safety should always be the top priority when operating all in one bag making machine as well as other types of machines. Here are some crucial safety measures to follow:

Training and education

Operators should receive comprehensive training on how to use the specific machine they will be working with. Training should cover machine setup, operation, maintenance, and emergency procedures. It is essential to ensure that all operators are fully aware of potential hazards and how to mitigate them.

Read the operator's manual

Each bag making machine comes with an operator's manual provided by the manufacturer. Operators must thoroughly read and understand this manual as it contains valuable information about machine specifications and safety guidelines. It also provides instructions for troubleshooting common issues.

Wear appropriate personal protective equipment (PPE)

Operators should wear the necessary PPE such as safety glasses, hearing protection, gloves and appropriate clothing. This protects from potential hazards caused by sharp edges, moving parts, and noise of paper bag machines as well as other machines.

Machine inspection and maintenance

Regular machine inspection and maintenance are critical to ensuring safe operation. Operators should perform daily checks to identify and address any issues promptly. This includes inspecting belts, chains, blades, and electrical components. Any damaged or worn parts should be replaced immediately to prevent accidents.

Machine guarding

Bag making machines often have moving parts such as rollers and cutting blades which can pose serious hazards if not properly guarded. Ensure that all moving parts are adequately fitted with safety guards to prevent accidental contact.

Lockout procedures

Before performing any maintenance tasks, operators should isolate the machine from its power source. They must use locks and tags to prevent accidents.

Emergency stop buttons

V bottom paper bag making machine as well as other types of machines should be equipped with easily accessible emergency stop buttons. Operators should be trained to use these buttons in case of an emergency.

Material handling

When working with materials like rolls of fabric or paper, it is essential to follow proper lifting techniques to prevent back injuries. Use lifting equipment or assistance when handling heavy or bulky materials.

Fire safety

Side sealing bag making machine may generate heat, sparks, or friction during operation. This increases the risk of fires. You must ensure that fire extinguishers are readily available and that operators are trained for their use. Moreover, you must keep the workspace clean and free from flammable materials.

Noise control

These machines can produce high levels of noise which can be harmful to operators' hearing. Implement noise control measures such as using hearing protection and maintaining the machinery to reduce noise levels.

Jiangxi Zhetuo Machinery Co., LTD., located in Jinbu Town, Yugan County, Shangrao City, Jiangxi Province, was established in September 2012. Is an annual output value of more than 100 million yuan of packaging machinery technology manufacturing enterprises.

Our Certificate

FAQ

Q: What is a side sealing bag making machine?

Q: How does a side sealing bag making machine work?

Q: What materials are used for side sealing bags?

Q: How does the paper bag machine work?

Q: What is the function of automatic sealing machine?

Q: What are the main components of a side sealing bag making machine?

Q: How does the sealing process work in a side sealing bag making machine?

Q: What are the advantages of using a side sealing bag making machine?

Q: How is the bag size adjusted in a side sealing bag making machine?

Q: Are side sealing bag making machines easy to maintain?

Q: How are sealed bags made?

Q: What is bubble film made of?

Q: What are some common issues with side sealing bag making machines?

Q: Are side sealing bag making machines safe to use?

Q: How does the cutting unit work in a side sealing bag making machine?

Q: Can side sealing bag making machines produce bags with different thicknesses?

Q: Are side sealing bag making machines noisy?

Q: How do you clean a side sealing bag making machine?

Q: How do you seal a pouch bag?

Q: Can you heat seal any bag?

Hot Tags: side sealing bag making machine, China side sealing bag making machine manufacturers, suppliers

You Might Also Like

Send Inquiry