Hey there! As a supplier of Bottom Seal Bag Machines, I often get asked about the bag - making flexibility of these machines. So, I thought I'd take the time to break it down for you all.

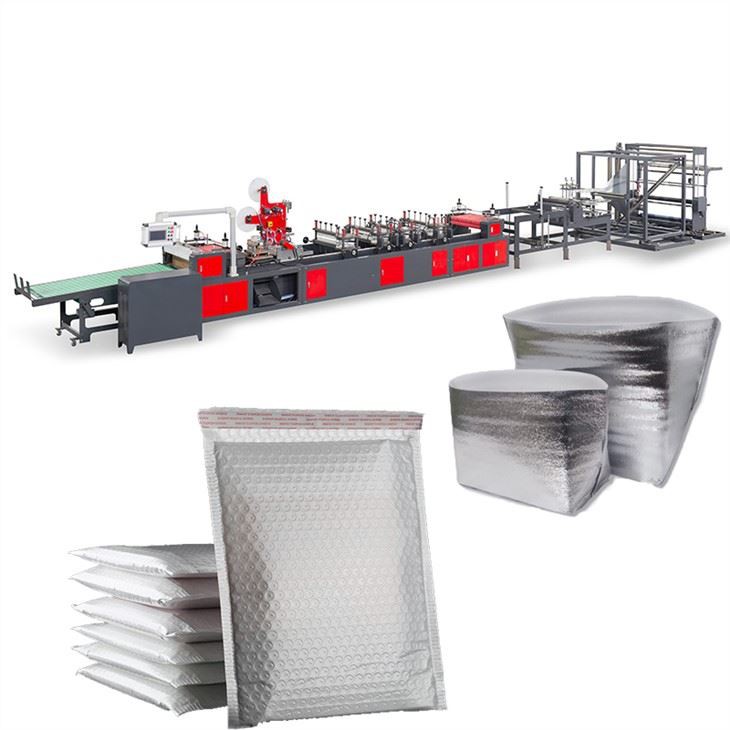

First off, let's talk about what a bottom seal bag machine actually does. Simply put, it's a piece of equipment that creates bags by sealing the bottom of the bag material. These machines are used in a wide range of industries, from food packaging to retail, because they're super efficient and can produce high - quality bags in large quantities.

One of the key aspects of the bag - making flexibility of a bottom seal bag machine is the variety of bag sizes it can handle. Most of our machines can produce bags in a wide range of lengths and widths. Whether you need small, snack - sized bags or large, heavy - duty ones for industrial use, our bottom seal bag machines can get the job done. For example, we can adjust the settings to make bags as small as a few inches in width and length for items like jewelry or small hardware, all the way up to bags that are several feet long for bulkier items.

The type of materials that these machines can work with is also a major factor in their flexibility. Our bottom seal bag machines can handle different types of plastics, such as polyethylene (PE) and polypropylene (PP). PE is a common choice because it's flexible, durable, and relatively inexpensive. It's great for everyday use, like packaging groceries or clothing. PP, on the other hand, is a bit stiffer and offers better heat resistance. It's often used for packaging hot - filled products or items that need to be sterilized.

Moreover, these machines can also work with laminated materials. Laminated bags have multiple layers, which can provide additional protection and functionality. For instance, a laminated bag might have a layer of aluminum foil for better moisture and oxygen barrier properties, making it ideal for food products that need to stay fresh for a long time.

Another cool thing about our bottom seal bag machines is their ability to create different bag styles. In addition to the standard flat - bottom bags, they can also make gusseted bags. Gusseted bags have expandable sides, which means they can hold more items. This is really useful for products like pet food, where you want to maximize the storage space in the bag.

Now, let's talk about the speed and efficiency of these machines. Our bottom seal bag machines are designed to be fast, which is crucial for businesses that need to produce a large number of bags in a short period of time. But here's the thing - even at high speeds, they still maintain a high level of quality. The seals are strong and consistent, so you don't have to worry about bags coming apart during transportation or storage.

When it comes to customization, our machines offer a lot of options. You can add features like zippers, tear notches, or handles to the bags. Zippers are great for reusable bags, as they allow customers to easily open and close the bag. Tear notches make it easier for consumers to open the bag without the need for scissors. And handles add convenience, especially for larger bags that need to be carried around.

If you're interested in other types of bag - making machines, we also have Side Sealing Bag Making Machine and Pp Bag Machine. The side - sealing bag - making machines work by sealing the sides of the bag material, which can be a great option for certain types of products. And our PP bag machines are specifically designed to work with polypropylene materials, producing high - quality PP bags. You can also check out our Side Sealing Bag Making Machine factory for more details.

In conclusion, the bag - making flexibility of our bottom seal bag machines is really impressive. They can handle a wide range of bag sizes, materials, styles, and can be customized to meet your specific needs. Whether you're a small business just starting out or a large corporation looking to upgrade your packaging process, our machines can provide a cost - effective and efficient solution.

If you're in the market for a bottom seal bag machine or have any questions about our products, don't hesitate to reach out. We're here to help you find the perfect bag - making solution for your business. Let's have a chat and see how we can work together to take your packaging to the next level.

References

- Industry knowledge and experience in bag - making machine manufacturing.

- Customer feedback and requirements analysis.