Stretch Film Machine

Jiangxi Zhetuo Machinery Co., LTD. established in September 2012, is an annual output value of more than 100 million yuan of packaging machinery technology manufacturing enterprises. We mainly produce various types of bubble film units, film blowing units, composite bubble envelope bag making machines, and buffer gas column bags for sale. The R&D center of the company can customize fully automatic packaging machinery and equipment for customers' needs.

Our Advantages

Advanced Technology

Our company has developed a 5-meter bubble film product and has become the only domestic manufacturer with this technology. Our R&D capabilities are industry-leading.

Rich Experience

We have an independent R&D team. The leader of the R&D team has more than ten years of R&D experience and can provide a variety of solutions for different needs.

ODM&OEM Available

We provide ODM and OEM services to many customers from more than 100 countries and regions, so that complete machine solutions can maximize the benefits for customers.

Lifetime Service

We have professional engineers who can handle various unexpected problems. What's more, after the warranty period, we will continue to provide long-term services to all customers, providing you with equipment upgrades and maintenance.

Products Description

The Shrink Wrap Machine Turntable mainly consists of rotating turntables and sealing systems. We place the products on the turntable and pack them through continuous rotation. The plastic film is also sealed to ensure that the product is fully wrapped, sealed, and protected.

The Machine Stretch Film is designed to withstand the pressure and impact of heavy loads and protect against moisture, dust, and contamination. At the same time, the maximum linear speed of the machine is 120m/min, which can effectively reduce the packaging volume and save packaging costs.

Low Profile Stretch Wrap Machine

The Low Profile Stretch Wrap Machine is an advanced packaging equipment that can automatically package products without manual intervention. This film can perfectly wrap the product inside and prevent the product from being damaged during transportation and storage.

Industrial Stretch Wrap Machine

The Industrial Stretch Wrap Machine is an automated packaging equipment. We have adopted the latest high-tech technology, which allows the machine to have a maximum extrusion capacity of 160 kg/hour.

Highlight Stretch Wrap Machine

The Highlight Stretch Wrap Machine is a kind of automatic packaging equipment. The machine can reduce the time to within minutes compared to traditional manual packaging. This feature can help businesses invest their time in other, more important tasks.

The Handheld Shrink Wrapper is a reusable packaging tool usually used for packaging small items. The maximum rolling width of our products is 500mmX2, and the maximum rolling diameter is 300mm.

The Hand Stretch Wrapping Machine is a machine for packaging items. The maximum winding width of the product is 500mmX3, and we also have a mechanical size of 12m*3.5m*2.5m.

The Handheld Stretch Wrapper is a device for packaging items by wrapping the packaging film around the item using a handheld device to protect and stabilize the item. By wrapping the packaging film tightly around the item, the item will be completely enclosed, reducing the impact and vibrations on it.

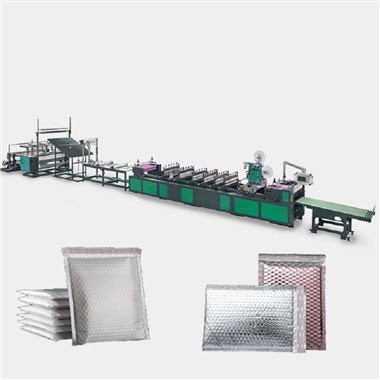

Air Bubble Film Making Machine

Scope of application: HPDE and LLDPE resins, etc.

Maximum mechanical speed: 40m/min (actual production speed is determined by conditions such as materials used and production process requirements)

Maximum extrusion volume: 300kg/h

Maximum extrusion thickness: 180gsm

A stretch wrap machine is a piece of equipment that automatically wraps pallets with stretch wrap. This keeps the products housed inside of the pallet contained and safe from damage.

Types of Stretch Wrappers

Turntable

A turntable stretch wrapping machine will feature a turntable, which is a round, revolving platform that turns in a circle while the stretch film is dispensed and applied to the pallet load. This kind of stretch wrapper is ideal for use with most applications, making it extremely versatile.

Rotary Arm

A mechanical arm that rotates around and wraps the pallet is the key feature of rotary arm stretch wrappers. This kind of stretch wrapper is ideal for use with loads that are on either end of the weight spectrum. Whether the load is super light or super heavy, a rotary arm will work with it perfectly.

Horizontal

A horizontal wrapper dispenses the stretch film from around a ring that surrounds a horizontally laid product. This kind of stretch wrapper is ideal for wrapping lengthy items that would otherwise be hard to wrap, such as windows, doors, lumber, textiles, copper piping, and corrugated tubes.

Advantages of Wrapping Your Products with a Stretch Wrapping Machine

Protection of Goods from Damage, Dust and Moisture

When you use the right stretch wrapping machine, it will ensure that your goods are securely wrapped to avoid any potential damage from dirt, dust, or moisture.

Saves Time

By investing in a wrapping machine, you will save a lot of time. Manually wrapping pallets, boxes and other products can be tedious and also time-consuming. However, wrapping your goods and boxes for storage or transportation with an automatic stretch wrapping machine will save you a lot of time and effort that you can use in other important business processes.

Improved Safety

A stretch wrapping system will keep your operator on the forklift which, in itself, is a safety measure. According to a recent survey, it was discovered that 20 percent of all forklift accidents involve people walking around the warehouse floor. Hand stretch wrapping causes wear-and-tear injuries, and upgrading to an automatic stretch wrapping machine will protect your employees. Automatic stretch wrappers require very little interaction from their operators. By simply pulling a cord from the forklift, it gets the pallet or goods wrapped. Additionally, the machine also ensures consistent wrapping that is safe and ready for transportation, while a manually wrapped pallet can easily topple and cause damage to your goods and the handler.

Save on Film Costs

Compared to hand wrapping, both semiautomatic and automatic stretch wrapping machines will save your business money on high film costs. Automatic stretch wrapping machines have two film thread rollers where the second rollers' rotational speed is higher than the first, and this stretches the film. This increases the tensile strength of the film and reduces the overall costs. Rotary tower automatic stretch wrapping machines are more efficient.

Faster Packaging

An automatic stretch wrapping machine with an enabled PLC control will aid in fastening the packaging process and help meet the bulk packaging requirements in your business. Stretch wrapping machines from Orion can be customized to fit your unique requirements. This is better than going for a regular machine with standard specifications, features, and accessories.

Efficient Product Wrapping

When you use a stretch wrapping system for all your bulk packaging business requirements, you can ensure consistency in wrapping your products with a similar stretch and efficiency which otherwise wouldn't be possible through hand stretch wrapping. The manual wrapping process has variations in the stretch and efficiency of packaging your products. This means that an automatic stretch wrapping machine will ensure better packaging of your boxes, pallets, and products at your workplace.

Increased Productivity

Who doesn't like the idea of getting more work done in less time? An automatic stretch wrapping machine will put your business on the path to efficiency. Your operators won't have to wait for the start and stop of wrapping cycles. With the placement of a pallet on a conveyor or pulling of a cord, the wrapping starts and stops automatically. From here the automatic stretch wrapping machines only get faster.

Improved Inventory Control

Stacking similar products together makes inventorying easier. This also reduces the chances of product separation that can make inventory counts time-consuming. However, with clear and consistent stretch wraps, you can scan straight through it if you are using a scanning system.

Machine Stretch Wrap VS Hand Stretch Film

Cost

One of the most important factors you must consider before choosing a wrapping method is the cost. Can you afford a stretch wrapping machine? If you can't afford it, hand stretch wrap is a better alternative.

Available Labour

Hand wrapping is labour-intensive. Therefore, you must pay attention to the number of employees available and the hours they can work. In the end, labour will amount to a high cost. If the cost is higher than buying a machine, upgrade to a machine wrapper to save cost.

Speed and Durability

Hand film is designed for manual application by a worker and can be even easier when you use a hand held shrink wrap dispenser. As a result, it is naturally the slower choice of the two. In contrast, machine film is faster and, as a result, is a better choice if you're processing a huge packaging volume. Not only this, but machine wrap is stronger than manual dispenser packaging. But you can use a hand stretch film if you don't need to wrap packages or move them over a long distance frequently.

Volume and Pallet Load Size

Pallets are often labelled with various load sizes in alphabetical order to help with differentiation. The type of pallet determines stretch wrap requirements. For example, Pallet type A refers to pallets with uniform shapes and zero puncture points. It is the easiest to wrap; hence, you can use a local gauge wrapper with minimal stress on the material's integrity. On the other hand, Type B has several puncture points, and you require a stretch wrap with higher performance to prevent tearing during shipping. No two loads are the same. As a result, you must first evaluate the size and shape of your load to determine if you require a strong or high-performance wrapper to prevent damage during transit.

Different Types of Stretch Film

Custom Colored Stretch Film

Colored stretch wraps and films are transparent packaging solutions offered in a broad spectrum of hues.Machine Stretch Film

As the name suggests, machine stretch film is designed to be applied by a machine. It offers several advantages over hand stretch film including efficiency, safety, speed, and lower materials cost. At the same time, machine stretch film leads to more secure loads.

Hand Stretch Film

Hand stretch film, in contrast to machine stretch film, is designed to be applied by hand. This type of film is regularly used in smaller capacity operations. While hand stretch film may not offer the efficiency, speed, and scale of machine stretch, it's an attractive option if you're looking to avoid the capital expense of a stretch film machine.

Pre-Stretched Types of Stretch Film

Pre-stretched film has been previously stretched to the limit or maximum breaking point. Because it has already been stretched, it doesn't require as much effort or energy in the application as a standard stretch film would need to achieve the same wrapping force.

UV Stabilized Stretch Film

UV stabilized stretch film offers weathering resistance and radiation absorption. Thanks to an extra UV blocker additive, this film can block out harmful UV radiation. Best of all, it's transparent, so you can still see through the film to identify the contents underneath.

Application of Stretch Wrapping Machine

Tissue and Sanitary Paper

Tissue products are very light and often sensitive to pressure. That's why they're regarded as being very unstable when packaged. Securing such products for shipping requires a high level of technical skill at the stretch-wrap machine as well as the best possible stretch film.

Drums and Hazardous Materials

Just imagine that your drums and hazardous materials were not sufficiently secured and an accident occurred while they were being shipped. You'd not only have to deal with damage to property and even injuries, you'd also face huge costs and paperwork.

Wood

Wood is a sensitive product that needs to be safeguarded from light and moisture and that needs to be protected during shipping. When coloured stretch films are used, care should be taken that they possess good opacity properties.

Working Principle of Stretch Film Machine

Automatic

As the name suggests, an automatic stretch wrapping machine does everything automatically. It carries a pallet to the wrap zone via roller conveyors. Once the machine is done wrapping the pallet, it sends it to the end of the packaging line down the exit conveyor. The next pallet is transferred to the wrap zone, and the process repeats.

Semi-Automatic

A semi-automatic stretch wrapper works similarly to an automatic one. The main difference between the two is that the semi-automatic stretch wrappers require an operator to be present to load and unload the pallet and if needed manually adjust the machinery throughout the process.

What Kind of Film?

There's more than one kind of stretch wrap. If you want maximum efficiency, you must use the correct film for your application. Cast film is transparent, glossy, and stretchy, but it's more resistant to tearing. Blown film is more opaque and less stretchy, but it's extremely durable and provides higher load retention. Want a mix between cast and blown? Go with machine wrap, which has the durability and load retention of blown film but the stretchiness of cast film. Do you have products that are susceptible to humidity? Perforated films can maintain optimal airflow.

Quality over Quantity

Ensure you choose a high-quality film. Investing in higher-quality films and the right gauge of film will save you from future headaches.

Check the Threading

The next tip on how to use a stretch wrap machine more effectively is to check the threading. If you thread the film incorrectly through the rollers, it will negatively impact machine performance. Not sure of the right way to thread the film? The user's manual or the machine itself should feature a threading diagram that shows you the correct way.

Containment Force is Key

The key to securely wrapping pallets is to pay attention to the containment force. Containment force holds your loads together. Each load requires a different amount of containment force depending on its size, shape, and weight.

Keep up With Maintenance

Make sure to clean your stretch wrap machines, grease any moving parts, and fix any problems as soon as they emerge. A machine that's worn-down and dirty won't operate as smoothly as a machine that you maintain properly.

Right Machine

If your stretch wrap machines are outdated or poorly designed, no amount of human intervention can save them. Swapping out worn-down machines with new ones will make your business instantly more productive.

Our Certificate

We have obtained the Certificate Of Machinery Directive, and the product reliability and safety are very high.

Our Factory

Zhetuo Machinery Co., Ltd. is a private company with a history of more than 10 years, with an annual output value of more than 90 million. The company adapts to the development of the global packaging machinery industry, and provides high-quality and low-cost machinery products for the vast number of new and old customers.

Ultimate FAQ Guide to Compound Air Bubble Film Machine

Q: What are stretch films used for?

Q: What is a stretcher film?

Q: What is the difference between stretch wrap and stretch film?

Q: Can I use stretch film for food?

Q: What type of film is stretch film?

Q: Is stretch wrap the same as plastic wrap?

Q: How long does stretch wrap last?

Q: Which industries use stretch film?

Q: What is stretch film made of?

Q: Is stretch film the same as cling film?

Q: Is stretch film shrink wrap?

Q: What is another name for stretch film?

Q: What is the most common stretch film?

Q: Can stretch wrap be reused?

Q: What is the difference between cast and stretch film?

Q: What's the difference between stretch film vs cling film?

Q: Is it necessary to have a stretch film machine in my packaging line?

Q: What are the maintenance requirements for a stretch film machine?

Q: What is the maximum film roll width that a stretch film machine can handle?

Q: How to stretch wrap a pallet?

Hot Tags: stretch film machine, China stretch film machine manufacturers, suppliers

You Might Also Like

Send Inquiry