Bubble Sheet Manufacturing Machine

Product winding maximum width: 1800mm (standard width 10mm-1800mm adjustable)

Product winding maximum diameter: 1500mm

Maximum mechanical speed: 40m/min (actual production speed is determined by conditions such as materials used and production process requirements)

Introduction

Bubble Sheet Manufacturing Machine is an important production equipment that can manufacture various types of bubble bags and bubble films. Many companies and factories use it to produce bubble bags and bubble films to protect the safety of their products, so this equipment is widely used in industries such as packaging, electronic products, and construction. It can automatically complete tasks such as cutting, die-cutting, and forming without manual intervention, thus greatly improving production efficiency and shortening the production cycle. In addition, the programmable control system can easily adjust the speed and temperature during the production process, ensuring product consistency and quality.

Features

Automated control system: Bubble Sheet Manufacturing Machine is controlled by a microcomputer, so parameters such as extrusion volume, bubble sheet width, length, and production speed can be adjusted directly by the operator on the human-machine interface. This design also allows for more accurate and uniform bag-making dimensions.

Automatic constant tension: The tension sensor, electronic control system, and motor drive device can be adjusted and controlled according to the properties and requirements of the bag material, thereby keeping the tension of the bubble material stable and preventing the material from deforming or wrinkles during the bag-making process. Therefore, bag-making quality and efficiency can also be improved.

High flexibility: The winding width of the Bubble Sheet Manufacturing Machine is 10-1800mm, and the maximum winding diameter reaches 1500mm. Customers can produce bubble bags according to their own needs and the size of the bubble bags is very flexible. At the same time, its production speed can reach 40m/min. Therefore, this equipment can meet the needs of most manufacturers.

Zhetuo Machinery is committed to producing bubble wrap machine, envelope bag machine and wrapping film machine. We have participated in numerous exhibitions, and our equipment has attracted countless customers.

List of auxiliary machines

Steel mixer

Suction machine

Chiller or Cooling tower

Recycling machine

| Scope of application: | HPDE and LLDPE resins, etc. |

| Product winding maximum width: | 1800mm (standard width 10mm-1800mm adjustable) |

| Product winding maximum diameter: | 1500mm |

| Maximum mechanical speed: | 40m/min (actual production speed is determined by conditions such as materials used and production process requirements) |

| Maximum extrusion volume: | 240kg/h |

| Maximum extrusion thickness: | 180gsm |

| Minimum extrusion thickness: | 50gsm |

| Extrusion thickness uniformity: | 3% |

| Mechanical voltage: | 3-phase 4-wire, 380V, 50HZ |

| Power supply: | 110KW |

| Mechanical size: | 11mX5.5mX3.5m (LXWXH) |

| Mechanical weight: | 7000KG |

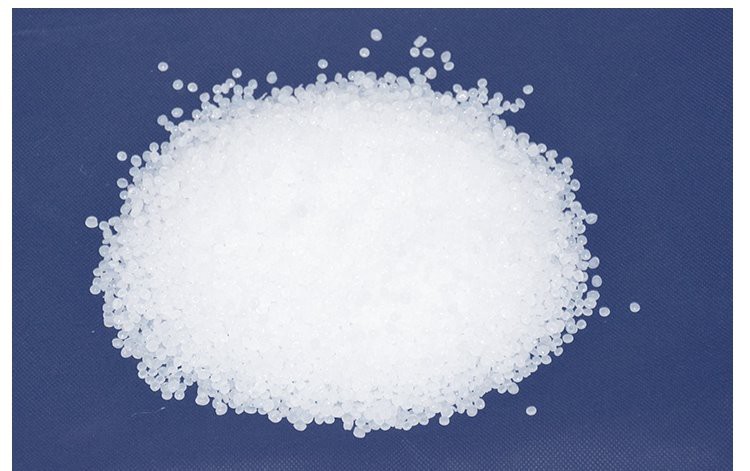

Raw materials of bubble film machine

HDPE, LDPE, LLDPE, 100% recycled

Our mode of transportation

Hot Tags: bubble sheet manufacturing machine, China bubble sheet manufacturing machine manufacturers, suppliers, smog bubble film machine, 7 Layers Air Bubble Film Machine, 7 Layers Polyethylene Bubble Wrap Machine, electric large bubble film machine, bubble wrap maker, Air Bubble Sheet Making Machine

You Might Also Like

Send Inquiry