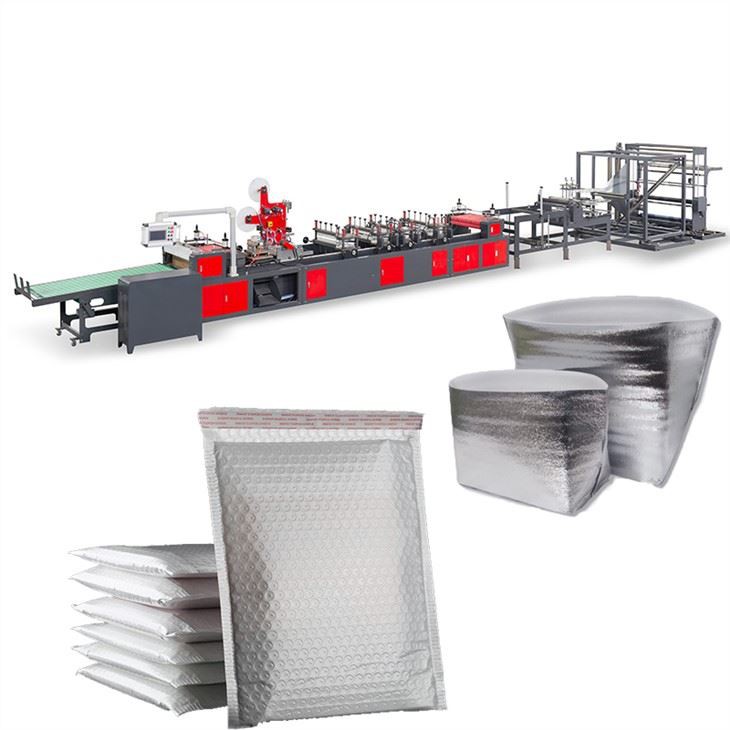

When it comes to using a bottom seal bag making machine, the workshop environment plays a crucial role in ensuring the machine's optimal performance, the quality of the produced bags, and the safety of the operators. As a trusted Bottom Seal Bag Making Machine supplier, we understand the significance of a suitable workshop environment and are here to share the key requirements.

Temperature and Humidity Control

Temperature and humidity are two of the most important environmental factors that can affect the operation of a bottom seal bag making machine. Extreme temperatures and high humidity levels can lead to various problems, such as material deformation, poor sealing quality, and mechanical failures.

Temperature

The ideal temperature range for operating a bottom seal bag making machine is typically between 20°C and 25°C (68°F - 77°F). At this temperature range, the materials used in bag making, such as plastic films, are more stable, and the machine's mechanical components can function smoothly.

If the temperature is too high, the plastic films may become too soft, which can cause issues during the cutting and sealing processes. For example, the seals may not be strong enough, or the bags may stick to the machine parts. On the other hand, if the temperature is too low, the films may become brittle, increasing the risk of breakage during production.

Humidity

Humidity also needs to be carefully controlled. The recommended relative humidity level is around 40% - 60%. High humidity can cause moisture to accumulate on the machine and the materials, leading to rust on the machine parts and affecting the adhesion of the seals. It can also make the plastic films more difficult to handle, as they may absorb moisture and become sticky.

Low humidity, on the other hand, can generate static electricity, which can attract dust and debris to the machine and the materials. This can not only affect the quality of the bags but also cause damage to the machine's electronic components. To maintain the appropriate humidity level, you can use dehumidifiers or humidifiers in the workshop.

Ventilation

Proper ventilation is essential in a workshop where a bottom seal bag making machine is used. During the bag making process, the machine generates heat, and some materials may release fumes or odors. Without adequate ventilation, the workshop can become hot and stuffy, which can be uncomfortable for the operators and may also affect the machine's performance.

Good ventilation helps to remove the heat generated by the machine, preventing overheating. It also helps to disperse any fumes or odors produced during the production process, ensuring a healthy working environment. You can install exhaust fans or ventilation ducts in the workshop to improve air circulation.

Cleanliness

A clean workshop is vital for the smooth operation of a bottom seal bag making machine. Dust, dirt, and debris can accumulate on the machine's moving parts, causing friction and wear. This can lead to mechanical failures and reduce the machine's lifespan.

Regular cleaning of the machine is necessary. You should clean the cutting blades, sealing bars, and other critical components daily to remove any residue. The workshop floor should also be kept clean to prevent dust from being kicked up and settling on the machine. Additionally, it is important to store the raw materials in a clean and dry place to avoid contamination.

Power Supply

A stable power supply is crucial for the proper functioning of a bottom seal bag making machine. Voltage fluctuations can damage the machine's electronic components and affect its performance. It is recommended to use a dedicated power supply line for the machine to avoid interference from other electrical equipment in the workshop.

You should also install a voltage stabilizer to ensure that the machine receives a consistent voltage. This can protect the machine from power surges and dips, which can cause malfunctions and even permanent damage.

Space Requirements

The workshop should have enough space to accommodate the bottom seal bag making machine and allow for easy operation and maintenance. There should be sufficient clearance around the machine for the operators to move freely and access all parts of the machine.

In addition, you need to consider the space for storing the raw materials and the finished products. Adequate storage space can help to keep the workshop organized and prevent clutter, which can pose safety hazards.

Safety Measures

Safety should always be a top priority in the workshop. When using a bottom seal bag making machine, there are several safety measures that need to be implemented.

Machine Guards

The machine should be equipped with appropriate guards to protect the operators from moving parts, such as belts, pulleys, and cutting blades. These guards should be properly installed and maintained to ensure their effectiveness.

Emergency Stop Buttons

Emergency stop buttons should be easily accessible from all sides of the machine. In case of an emergency, the operators can quickly stop the machine to prevent accidents.

Operator Training

All operators should receive proper training on how to operate the bottom seal bag making machine safely. They should be familiar with the machine's controls, safety features, and emergency procedures. Regular safety training sessions should be conducted to reinforce safety awareness.

Complementary Equipment

In addition to the bottom seal bag making machine, there are some complementary equipment that can enhance the workshop environment and the production process. For example, you may consider using a Non Woven Box & loop Handle Bag Making Machine if you want to produce non - woven bags with box and loop handles. This machine can work in tandem with the bottom seal bag making machine to expand your product range.

Another option is the OPP Thermal Cutting And Bag Making Machine, which is suitable for making OPP bags. It can provide more flexibility in your bag production.

The Side Sealing Bag Making Machine is also a useful addition if you need to produce side - sealed bags. These machines can complement each other and improve the overall efficiency of your workshop.

In conclusion, creating a suitable workshop environment is essential for the successful operation of a bottom seal bag making machine. By paying attention to temperature, humidity, ventilation, cleanliness, power supply, space requirements, and safety measures, you can ensure the machine's optimal performance, produce high - quality bags, and provide a safe working environment for your operators.

If you are interested in our bottom seal bag making machines or need more information about creating the right workshop environment for them, please feel free to contact us for procurement and negotiation. We are committed to providing you with the best solutions and support.

References

- Bag Making Machine Operation Manuals

- Industry Standards for Plastic Bag Manufacturing Workshops