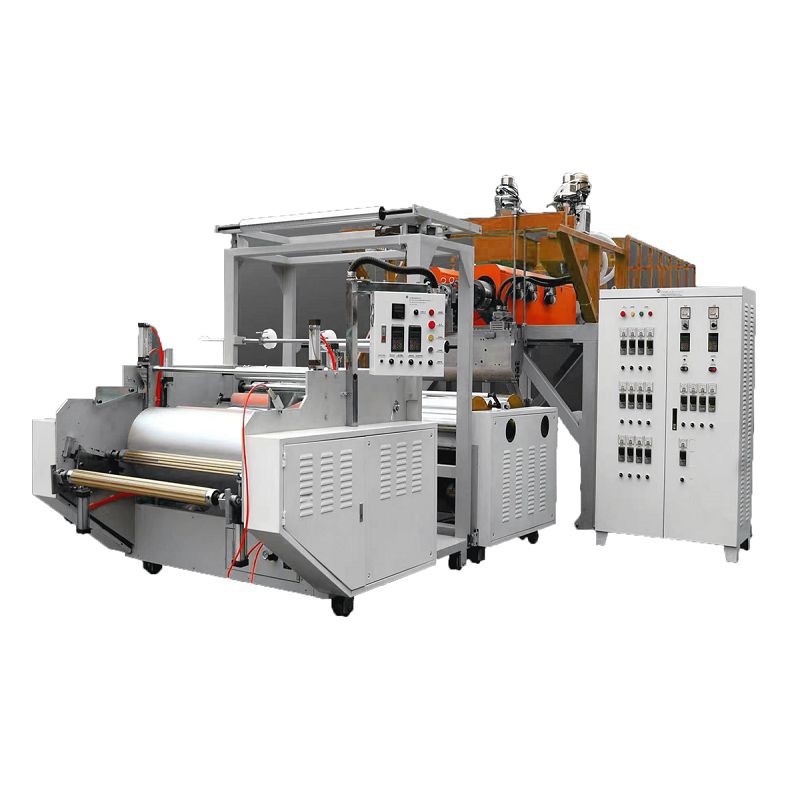

Maintaining a Highlight Stretch Wrap Machine is crucial for businesses that rely on efficient packaging solutions. As a supplier of the Highlight Stretch Wrap Machine, I understand the importance of keeping these machines in top - notch condition. In this blog post, I'll share some essential tips on how to maintain your Highlight Stretch Wrap Machine to ensure its longevity and optimal performance.

Regular Cleaning

The first step in maintaining your Highlight Stretch Wrap Machine is regular cleaning. Over time, dust, debris, and remnants of the stretch film can accumulate on the machine's components. This build - up can cause mechanical problems, such as jams and reduced efficiency.

- Exterior Cleaning: Use a soft, dry cloth to wipe down the exterior of the machine regularly. This will remove any surface dust and prevent it from entering the internal parts. If there are stubborn stains, you can use a mild cleaning solution, but make sure to dry the machine thoroughly afterward to avoid rusting.

- Internal Cleaning: For the internal components, such as the film carriage and the rollers, it's important to clean them more carefully. First, turn off the machine and unplug it from the power source. Use a small brush or compressed air to remove any debris from hard - to - reach areas. Be especially careful around the sensors and electrical components to avoid damage.

Lubrication

Proper lubrication is essential for the smooth operation of the Highlight Stretch Wrap Machine. Moving parts, such as the chains, gears, and bearings, need to be lubricated regularly to reduce friction and wear.

- Selecting the Right Lubricant: Choose a lubricant that is suitable for the machine's components. For most Highlight Stretch Wrap Machines, a light - weight machine oil or a specialized food - grade lubricant (if the machine is used in food packaging applications) is recommended. Avoid using heavy - duty greases that can attract dust and debris.

- Lubrication Schedule: Follow the manufacturer's recommendations for lubrication intervals. Generally, it's a good idea to lubricate the machine every few weeks or after a certain number of operating hours. Make sure to apply the lubricant evenly to all the moving parts, and wipe off any excess to prevent it from dripping onto the film or other components.

Inspection of Components

Regular inspection of the machine's components is another important aspect of maintenance. This can help you identify potential problems before they become serious and lead to costly repairs.

- Film Roll and Carriage: Check the film roll regularly to ensure that it is properly loaded and that there are no signs of damage or wear. Inspect the film carriage for any loose or damaged parts, such as the tensioning mechanism and the guide rollers. If you notice any issues, replace the damaged parts immediately.

- Sensors and Electrical Components: The sensors and electrical components of the Highlight Stretch Wrap Machine are critical for its proper operation. Check the sensors for any signs of dirt or damage, and clean them if necessary. Inspect the electrical wiring for any loose connections, frayed wires, or signs of overheating. If you are not experienced with electrical systems, it's best to have a professional technician perform this inspection.

- Frame and Structure: Examine the machine's frame and structure for any signs of cracks, dents, or misalignment. A damaged frame can affect the machine's stability and performance. If you find any issues, contact the manufacturer or a qualified repair technician for assistance.

Calibration

Calibration is necessary to ensure that the Highlight Stretch Wrap Machine is operating at its optimal settings. Over time, the machine's settings may drift, resulting in inconsistent wrapping quality.

- Film Tension Calibration: The film tension is a critical parameter that affects the quality of the wrap. Use the machine's calibration tools to adjust the film tension according to the type and thickness of the stretch film you are using. A proper film tension will ensure that the film is wrapped tightly around the load without tearing or stretching too much.

- Wrapping Speed and Pattern Calibration: Adjust the wrapping speed and pattern settings to match the specific requirements of your loads. Different loads may require different wrapping speeds and patterns to achieve the best results. Refer to the machine's user manual for detailed instructions on how to calibrate these settings.

Operator Training

Proper operator training is often overlooked but is one of the most important factors in maintaining the Highlight Stretch Wrap Machine. Well - trained operators are more likely to use the machine correctly, which can prevent unnecessary wear and tear.

- Initial Training: Provide comprehensive training to new operators on how to use the machine safely and efficiently. This should include instructions on loading the film, adjusting the settings, and performing basic maintenance tasks.

- Ongoing Training: Offer ongoing training to keep operators up - to - date with the latest features and best practices. Regularly review the safety procedures and maintenance requirements with the operators to ensure that they are following the correct protocols.

Storage

If you need to store the Highlight Stretch Wrap Machine for an extended period, proper storage is essential to prevent damage.

- Clean and Prepare the Machine: Before storing the machine, clean it thoroughly and lubricate all the moving parts. Remove any remaining film from the machine to prevent it from drying out and sticking to the components.

- Store in a Suitable Location: Store the machine in a dry, clean, and temperature - controlled environment. Avoid storing the machine in areas where it may be exposed to moisture, dust, or extreme temperatures. If possible, cover the machine with a protective cover to prevent dust and debris from accumulating on it.

In addition to the Highlight Stretch Wrap Machine, we also offer other related machines, such as the Multilayer Stretch Film Coextrusion Machine and the Automatic Shrink Wrap Machine For Pallets. These machines can complement your packaging operations and provide you with a more comprehensive packaging solution.

Maintaining your Highlight Stretch Wrap Machine is not only about ensuring its proper operation but also about maximizing its lifespan and reducing the overall cost of ownership. By following these maintenance tips, you can keep your machine running smoothly and efficiently for years to come.

If you have any questions about maintaining your Highlight Stretch Wrap Machine or are interested in purchasing one of our machines, please feel free to contact us. We are always ready to provide you with professional advice and support to meet your packaging needs.

References

- Manufacturer's user manual for Highlight Stretch Wrap Machine

- Industry best practices for stretch wrap machine maintenance