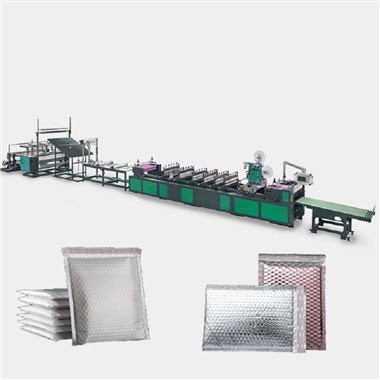

Air Bubble Wrap Making Machine

Why Choose Us?

Quality products: We have advanced production and testing equipment, and our products meet various standards.

Rich experience: We have years of industry experience and a team of experienced engineers and technicians to ensure consistent precision and high quality of our products.

Reliable service: Our team is committed to providing reliable and consistent service, ensuring that you receive high-quality products and customer support from us every time.

Professional team: The company is in possession of numbers of senior engineers and has abundant technique power, well conditioned equipment and technology comes to perfection.

What Is Air Bubble Wrap Making Machine

The machine works by feeding plastic film into a series of rollers that create pockets of air, which are then sealed to create the familiar bubble wrap texture. An air bubble wrap making machine is a type of equipment used in the manufacturing process of air bubble wrap, which is a packaging material consisting of two layers of polyethylene film with air bubbles trapped between them.

Benefits of Air Bubble Wrap Making Machine

Cost-effective

By producing your own bubble wrap and protective packaging materials in-house, you can reduce the overall packaging costs and save money.

Customizable

Air bubble film extrusion machines offer flexibility in terms of bubble size, thickness, and spacing, allowing you to create customized packaging materials that meet the specific needs.

Increased efficiency

With an air bubble film machine, you can produce bubble wrap and other protective materials quickly and easily, streamlining the packaging process and increasing the overall efficiency.

Better protection for products

Bubble wrap and other protective materials created by air bubble film machines provide excellent cushioning and shock absorption, reducing the risk of damage to products during shipping and storage.

Common Types of Air Bubble Wrap Making Machine

These machines produce a single layer of bubble wrap and are suitable for smaller-scale production needs.

These machines produce a double layer of bubble wrap, providing increased protection for fragile items during shipping.

In addition to the single-layer air bubble film machines and double-layer air bubble film machines, there are other variations available, including 3-layer to 10-layer air bubble film machines. These machines are capable of producing multi-layered bubble wrap with varying degrees of thickness and durability, making them ideal for protecting items during shipping and storage.

These machines can produce bubble wrap at high speeds, making them ideal for large-scale production needs.

These machines are fully automated, with features like auto-roll changing and cutting, making them highly efficient and suitable for high-volume production.

Blown film manufacturing is a crucial process in the production of various plastic films and polybags used in a wide range of industries. With the increasing demand for flexible packaging solutions, it is essential to have a comprehensive understanding of the basics of blown film manufacturing.

Blown Film Manufacturing Process

The blown film manufacturing process involves the transformation of plastic resins into thin, continuous films through the use of specialized machinery. It is a complex and intricate process that requires expertise and precision to ensure the production of high-quality films.

Extrusion

The first step in blown film manufacturing is extrusion. Plastic resins, such as polyethene (PE) or polypropylene (PP), are melted and formed into a molten state using an extruder. The extruder consists of a screw that conveys the resin through a heated barrel. The heat and pressure applied during this stage facilitate the melting and homogenisation of the resin.

Film Formation

Once the molten resin is prepared, it is forced through a circular die head, which shapes the resin into a tube. Air is introduced into the centre of the tube, causing it to expand while maintaining its cylindrical shape. This process is known as bubble or tube formation. The size of the die, air flow rate, and extrusion speed determine the final dimensions and thickness of the film.

Cooling and Orientation

As the tube expands, it moves upwards and is simultaneously cooled by air or water. Cooling solidifies the molten resin, forming a stable film structure. The speed at which the film is pulled from the die determines the orientation and mechanical properties of the film. Stretching the film during this stage can enhance its strength, clarity, and barrier properties.

Take-off and Winding

After the film has been cooled and solidified, it is pulled away from the die by a set of nip rollers or collapsing frames. These rollers control the tension and speed at which the film is taken off. The film is then wound onto a roll, allowing for easy handling and storage.

The Intricate Journey of Crafting an Air Bubble Wrap Making Machine

In the bustling world of manufacturing, the creation of an air bubble wrap making machine represents a symphony of engineering precision, innovation, and meticulous craftsmanship. This machine, pivotal in safeguarding products during transportation and storage, undergoes a fascinating process from conception to completion.

Conceptualization and design

The journey begins in the minds of engineers and designers who conceptualize the machine based on market needs, safety standards, and technological advancements. Using sophisticated software, they draft detailed blueprints that outline the machine's architecture, components, and functionality. This phase is crucial for laying down the foundation upon which the entire manufacturing process is built.

Material selection

Once the design is finalized, the next step involves selecting high-quality materials that ensure durability and efficiency. The choice of materials ranges from metals for the structure to plastics and rubbers for insulation parts. Each material is chosen based on its ability to withstand wear and tear, its compatibility with other components, and its contribution to the overall performance of the machine.

Component fabrication

With materials at hand, specialized machinery such as CNC (computer numerical control) machines are employed to fabricate individual components with high precision. This step involves cutting, shaping, drilling, and milling operations to transform raw materials into specific parts required for assembly. The accuracy during this phase is paramount to ensure that all components fit together seamlessly.

Assembly

The assembly stage is where all fabricated parts come together to form a functional air bubble wrap making machine. Skilled technicians meticulously follow engineering blueprints to assemble components correctly. This process often involves welding, bolting, and mounting various parts while ensuring that moving elements like rollers and motors are aligned perfectly.

Electrical system integration

An integral part of making the machine operational involves integrating electrical systems that power it. Electrical engineers install wiring, control panels, sensors, and software that enable users to operate the machine efficiently. This step requires a deep understanding of electrical safety standards to ensure that the machine operates safely under all conditions.

Testing and quality assurance

Before declaring the air bubble wrap making machine ready for market release, it undergoes rigorous testing to ensure it meets all performance criteria. This includes testing its durability under continuous operation conditions, verifying safety features are functional, and ensuring it produces bubble wrap according to specifications. Any issues identified are addressed promptly to guarantee a high-quality product.

The Benefits of Bubble Wrap

Bubble wrap is lightweight:Bubble wrap is very lightweight and easy to carry, use and store.

Bubble wrap can be reused:Bubble wrap can be reused many times as it can be cut into individual pieces. This helps save money because it means you do not have to buy new bubble wrap as often as you would if you were to buy packing paper or other packing materials designed to protect your items.

Bubble wrap is easy to use:When it comes to utilizing the protection capabilities of bubble wrap, its really quite simple. You just wrap your items in bubble wrap and store them wherever they need to be stored for transport. Super easy!

Bubble wrap is durable:Bubble wrap can last for a long time if it is stored properly. This makes it very useful for protecting fragile items for a long time, such as computers, phones, and other electronic devices. It also means that it does not need to be replaced frequently if you are storing something for a long time, which saves money in the long run. Bubble wrap is also more durable than packing paper or foam because it is able to absorb more shock when things are dropped.

Bubble wrap is versatile:Bubble wrap can be cut into small pieces to protect smaller items such as DVDs, CDs, and even books. It can also be wrapped around small objects such as figurines and statues to keep them safe from damage.

Components of Air Bubble Wrap Making Machine

1. Extruder: The extruder is the primary component of the machine responsible for melting and mixing the raw materials, typically low-density polyethylene (LDPE) pellets, to form a molten plastic resin.

2. Bubble Forming Unit wrap: The machine consists of several key components that work together to produce the air bubble wrap. Here bubble forming are the main components of an air bubble wrap making machine:

3. Extruder: The extruder is the primary component of the machine responsible for melting unit is and mixing plastic resins to form a molten where the molten plastic resin is shaped into bubbles using a cylindrical die polymer. The molten polymer is then forced through a die to create a continuous film.

4. Air is Bubble Forming Unit: This unit consists of rollers and guides that shape the molten polymer blown into these bubbles to create film into a tube-like structure with air the characteristic air pockets in the bubbles trapped inside. bubble wrap The size.

5. Cooling Unit: Bubbles can be adjusted After the bubbles are based on the requirements formed, they pass through a cooling unit where they solidify After the bubble forming process, the film needs to be cooled down quickly to solidify and stabilize the air bubbles and cool down to maintain their shape and structure.

6. Roller System: The roller system consists of. A cooling system rollers that guide and transport the bubble wrap, such as chilled rollers or air cooling through various stages of units, is used for this purpose.

7. Slitting and Cutting Mechanism: This component is responsible for slitting the wide sheet of bubble wrap into smaller rolls of desired widths it needs to be slit into smaller rolls of desired widths. The slitting unit cuts the film into multiple rolls and cutting them to specific lengths, which are then.

8. Winding Unit: The wound onto individual cores for storage winding unit rolls up the finished bubble wrap and transportation.

9. Control Panel: The control panel houses all the necessary controls such as temperature, speed, pressure, and bubble size. It allows for precise and settings for operating and monitoring the machine control over the production process.

10.Tension Control System: To ensure uniform quality and thickness of the air's performance, including temperature controls, speed adjustments, and emergency stop buttons.

11. Air Compressor: An air compressor supplies compressed air to inflate the bubbles during bubble wrap film, a tension control system is used to maintain consistent tension levels throughout the production process.

12. Heating Elements: Heating elements are used to melt the Some machines may include a cutting mechanism that trims excess material from the edges of the film or cuts plastic resin in the extruder and maintain it at an optimal temperature throughout the process.

13. Sensors and Safety Features: It into specific lengths as required.

14. Safety Features: Safety features such as emergency stop buttons, guards, sensors, and alarms are essential components to ensure safe operation and prevent accidents in the Various sensors are incorporated into the machine to monitor parameters such as temperature, pressure, and speed workplace.

How to Choose Air Bubble Wrap Making Machine

Packaging volume: Assess the average and peak packaging volumes. This will help determine the capacity and speed required in a air bubble wrap making machine. Choosing a machine that aligns with production levels will avoid bottlenecks and ensure smooth operations.

Product diversity: Consider the range of products being packaged. If handling items of varying sizes, shapes, and fragility, opt for a machine with adjustable settings and customization options. Versatility is key to accommodating diverse packaging needs.

Material compatibility: Different machines may be designed for specific materials. Ensuring the chosen machine is compatible with the bubble wrap material intended to be used is essential. Some machines can accommodate various bubble wrap sizes and materials, offering more flexibility.

Automation level: Determining the degree of automation that best suits the workflow is important. Some machines offer fully automated processes, while others may require manual adjustments. Balancing automation with the desired level of control in packaging operations is necessary.

Dispensing mechanism: Consider whether a machine dispenses pre-cut bubble wrap sheets or one that allows customizing the length of bubble wrap based on the product dimensions is preferred. The latter option can minimize material waste.

Speed and efficiency: Evaluate the machine's packaging speed and impact on the production timeline. Opting for a machine that strikes the right balance between speed and consistent bubble wrap application is recommended.

Ease of use: Choosing a user-friendly machine that requires minimal staff training is important. Complicated machines can lead to operational delays and errors.

Research and comparison: Thoroughly research different machine models and brands. Comparing features, customer reviews, and performance to identify machines that align with requirements is recommended.

Durability and maintenance: Consider the durability of the machine and its maintenance requirements. Machines with a reputation for reliability and easy maintenance will minimize downtime and maintenance costs.

Warranty and support: Check the warranty the manufacturer offers and the availability of customer support. A strong warranty and accessible support can provide peace of mind and timely assistance if issues arise.

Tips for Maintaining Your Air Bubble Wrap Making Machine

Here are tips on how to invest and maintain the right air bubble wrap making machine:

Perform routine maintenance

Conduct regular inspections and service of key parts like the forming cylinder, cutting unit, and sealing unit. Clean and lubricate moving parts to prevent overheating and ensure proper operation.

Check and replace worn parts

Examine parts like the cutting blades, sealing tapes or glue rolls, and forming plates for any signs of wear and tear. Dull or damaged parts will produce low-quality bags and reduce productivity. Have spare parts on hand to swap them out when needed quickly.

Keep the area clean

Maintain a clean workspace around your air bubble wrap making machine. Wipe up any oil, cream or debris which can be a slipping hazard or interfere with the equipment. Place trash receptacles nearby for waste paper scraps and trimmed edges. A clean, uncluttered area will allow for easier operation and maintenance.

Perform test runs

Conduct trial runs with scrap paper to ensure the machine functions properly after servicing or part replacements. Check that bags are cutting, sealing, and forming correctly at various speed settings. Make any final tweaks to the machine before resuming full production.

Whether packaging small, delicate items or large, irregularly shaped ones, properly securing the bubble wrap is pivotal in providing adequate cushioning and protection. Fragile materials, including glass, porcelain, and electronics, require additional care and cushioning during packaging. Employing more intricate wrapping techniques for items with irregular shapes or protruding parts is advisable.

The packaging needs to provide stronger cushioning when dealing with heavier items due to the potential pressure exerted. Items susceptible to impact damage, such as electronics, should be protected thoroughly. In cases where multiple items are stacked or layered within the same package, ensure that each item is adequately cushioned to prevent direct contact and possible damage.

● Wrapping individual items: Regardless of the item's size, whether small, medium-sized, or large and irregularly shaped, the objective is to create a barrier that shields it from potential impacts.

● Small to medium-sized items: Lay the bubble wrap flat and position the item at the centre. Fold the bubble wrap over the item, ensuring complete coverage. This method provides a layer of cushioning that guards against shocks and vibrations.

● Large and irregularly shaped items: Use multiple sheets of bubble wrap to envelop the item thoroughly. Overlapping the layers of bubble wrap creates a cushioned cocoon that effectively absorbs any impacts.

● Securing the bubble wrap: After wrapping the item, securing the bubble wrap is vital to maintaining its protective integrity. This can be achieved through either tape or self-adhesive bubble wrap.

● Ensuring complete coverage: When wrapping items, consider corners, edges, and any particularly vulnerable points. Adding extra layers of bubble wrap to these areas can provide enhanced protection. The goal is to create a sturdy and reliable cushioning barrier that minimizes the risk of damage.

Essential Precautions for Safely Operating an Air Bubble Wrap Making Machine

Understand the Machine Thoroughly

Before even switching on the machine, it is imperative that operators are fully trained and familiar with every aspect of its operation. This includes understanding its mechanics, the function of each part, and how they interrelate. Comprehensive knowledge will not only improve efficiency but also minimize the risk of accidents.

Regular Maintenance Checks

Routine maintenance is vital for keeping the machine in optimal working condition. This involves checking for any wear and tear on parts, ensuring that all components are well-lubricated, and replacing any parts that are worn out or damaged. Neglecting maintenance can lead to unexpected breakdowns or accidents.

Wear Appropriate Safety Gear

Operators should always wear proper safety gear which includes gloves, safety glasses, and ear protection if necessary. The machinery can produce high levels of noise which could be harmful over long periods, and there is always a risk of coming into contact with moving parts or heated elements.

Keep Work Area Clean and Organized

A cluttered workspace can lead to accidents. Ensure that the area around the air bubble wrap making machine is clean and free from any obstacles that could cause trips or falls. Additionally, keeping tools organized will help in maintaining a safe working environment.

Follow Operational Guidelines

Every machine comes with a set of operational guidelines provided by the manufacturer. These should be followed meticulously to ensure safe operation. Deviating from these guidelines not only risks damaging the machine but also endangers the operator.

Emergency Shutdown Procedures

Operators must be well-versed in emergency shutdown procedures in case something goes wrong during operation. Knowing how to quickly and safely shut down the machine can prevent accidents from escalating into serious injuries or damage.

Avoid Distractions

Operating heavy machinery requires full attention. Distractions such as using a mobile phone or engaging in conversations while operating the machine should be strictly avoided to prevent accidents.

Proper Training for All Operators

Only individuals who have received proper training should be allowed to operate the air bubble wrap making machine. This ensures that everyone using the machine understands how to do so safely and efficiently.

Jiangxi Zhetuo Machinery Co., LTD., located in Jinbu Town, Yugan County, Shangrao City, Jiangxi Province, was established in September 2012. Is an annual output value of more than 100 million yuan of packaging machinery technology manufacturing enterprises.

Our Certificate

FAQ

Q: How do they get air into bubble wrap?

Q: What is the purpose of bubble wrap?

Q: Should bubble wrap bubbles be inside or outside?

Q: How do you use bubble wrap effectively?

Q: Does bubble wrap protect from moisture?

Q: What are the features of bubble wrap?

Q: What is the manufacturing process of air bubble film?

Q: How is bubble wrap manufactured?

Q: Why do bubble wraps have air filled bubbles?

Q: What are the components of bubble wrap?

Q: How much bubble wrap is made each year?

Q: What is an air bubble wrap making machine?

Q: How does an air bubble wrap making machine work?

Q: What is the manufacturing process of paper bags?

Q: What machine is used to print on paper bags?

Q: What are the main components of an air bubble wrap making machine?

Q: What types of plastic films can be used with an air bubble wrap making machine?

Q: What are the advantages of using an air bubble wrap making machine?

Q: Is bubble wrap hazardous?

Q: Which gas is filled in bubble wrap?

Hot Tags: air bubble wrap making machine, China air bubble wrap making machine manufacturers, suppliers, giant bubble film maker, polybag manufacturing machine, paper bag making machine germany, bopp plastic bag making machine, package shrink wrap machine, automatic shrink wrap machines

Previous

No InformationYou Might Also Like

Send Inquiry