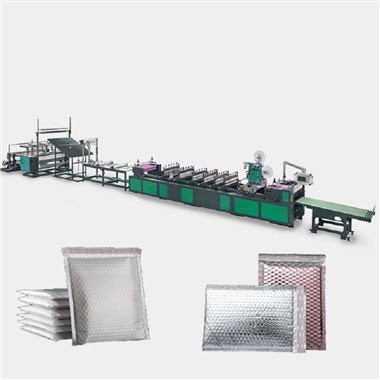

Air Bubble Bag Machine

Why Choose Us?

Quality products: We have advanced production and testing equipment, and our products meet various standards.

Rich experience: We have years of industry experience and a team of experienced engineers and technicians to ensure consistent precision and high quality of our products.

Reliable service: Our team is committed to providing reliable and consistent service, ensuring that you receive high-quality products and customer support from us every time.

Professional team: The company is in possession of numbers of senior engineers and has abundant technique power, well conditioned equipment and technology comes to perfection.

What is Air Bubble Bag Machine?

Air bubble bag machine is a specialized equipment designed to produce bubble wrap and other protective packaging materials. The machine work by feeding plastic film into a series of rollers that create pockets of air, which are then sealed to create the familiar bubble wrap texture.

Benefits of Air Bubble Bag Machine

Cost-effective

By producing your own bubble wrap and protective packaging materials in-house, you can reduce the overall packaging costs and save money.

Customizable

Air bubble film extrusion machines offer flexibility in terms of bubble size, thickness, and spacing, allowing you to create customized packaging materials that meet the specific needs.

Increased efficiency

With an air bubble bag machine, you can produce bubble wrap and other protective materials quickly and easily, streamlining the packaging process and increasing the overall efficiency.

Better protection for products

Bubble wrap and other protective materials created by air bubble bag machine provide excellent cushioning and shock absorption, reducing the risk of damage to products during shipping and storage.

Not only is air bubble bag perfect for protecting items, but bubble packing wrap also makes a good insulator. Air in a confined space tends to resist temperature changes as the air molecules move around, making the transfers of energy more difficult. Since bubble wrap is nothing more than bubbles of air wrapped in plastic this is a popular option for insulating houses and other premises.

There are several advantages for using air bubble bag as an insulator. Firstly, it can be easily cut with scissors to fit any shape or size. It can be applied without the need for any technical requirements. Due to its lightweight nature, bubble wrap can be transferred from one place to another without any issues. It can be attached to windows by simply spraying water on the glass and pressing the bubble wrap to it, eliminating the need for adhesives.

Bubble wrap can also be reused, depending on whether it remains in good shape with the bubbles still intact, to last for several seasons.

Components of Air Bubble Bag Machine

Air Bubble Film Roll: The machine requires a roll of air bubble film, which is typically made of two layers of polyethylene film with air bubbles trapped between them. This roll serves as the raw material for producing the air bubble bags.

Unwinding System: The unwinding system is responsible for feeding the air bubble film roll into the machine at a controlled speed. It ensures a continuous supply of film for the production process.

Heating System: The heating system in the machine is used to soften and melt the polyethylene film layers, allowing them to bond together and form the air bubbles in between. This process creates the characteristic cushioning effect of air bubble bags.

Air Injection System: The machine is equipped with an air injection system that pumps air into the space between the two layers of polyethylene film as they pass through the heating element. This creates the individual air bubbles that give the bags their protective properties.

Sealing System: Once the air bubbles are formed, a sealing system seals the edges of the film layers together to enclose the bubbles and create a continuous sheet of air bubble material.

Cutting Mechanism: After sealing, a cutting mechanism cuts the continuous sheet of air bubble material into individual bags of desired lengths. This allows for customization based on specific packaging needs.

Control Panel: The control panel on an air bubble bag machine allows operators to set parameters such as speed, temperature, and bag length. It provides a user-friendly interface for monitoring and adjusting production processes.

What Types of Materials Are Used to Make Air Bubble Bags

This is the most common material used in the production of air bubble bags. Polyethylene is a type of plastic that is lightweight, flexible, and resistant to water. It's available in various densities, but for air bubble bags, low-density polyethylene (LDPE) is typically used due to its ability to form thin films that are excellent for producing the air bubbles.

Sometimes, a layer of nylon is added to air bubble bags to increase their strength and puncture resistance. Nylon is a synthetic polymer known for its toughness and elasticity. When combined with polyethylene, it enhances the barrier properties against gases and odors, making the air bubble bag more durable.

For applications requiring additional protection against temperature fluctuations or electromagnetic interference (EMI), a metalized film can be laminated to the surface of polyethylene bubbles. This film usually consists of aluminum vapor coated onto a polymer base, offering reflective properties that help in insulation or shielding.

With increasing awareness about environmental sustainability, some manufacturers are incorporating recycled plastics into their production process for air bubble bags. These materials may include post-consumer or post-industrial recycled polyethylene, which helps reduce waste and conserve resources without significantly compromising the quality of the final product.

These are multi-layer films made by extruding several layers of different polymers simultaneously. Co-extrusion can combine the advantageous properties of various polymers in one film, such as improved mechanical strength or barrier properties against moisture and gases.

The packaging industry is an important sector that has played a vital role in both the manufacturing and retail sectors. Packaging is the process of enclosing products or goods to ensure their safety during transportation and handling. Packaging plays a crucial role in protecting the goods, preserving their quality, and ensuring their integrity from the factory to the consumer. One of the essential tools used in the packaging industry is the air bubble bag machine.

The primary purpose of the air bubble bag machine is to protect the products against damages caused by vibration, shock, and impact during transportation and handling. The air bubble bag machine is designed to create bubble bags that provide a cushioning effect that absorbs the pressure and impact on the products, ensuring their safety and protection.

The air bubble bag machine is versatile, which means it can be used for packaging a wide range of products, including fragile and delicate materials. The machine can create different sizes and shapes of air bubble bags, depending on the products to be packaged. The machine can produce small, medium, and large bubble rolls that can be used to pack different sizes of products.

The air bubble bag machine is cost-effective, which means it is affordable, and it helps in reducing packaging costs. The machine produces air bubble bags in bulk, which reduces the packaging cost per unit. Also, the machine is easy to operate, which means it reduces labor costs, making it a cost-effective option for companies.

The packaging of products is an important aspect of branding. The air bubble bag machine provides an efficient way of packaging products, which improves the brand image. The bubble bags provide a professional and attractive packaging that enhances the appearance of the products.

The air bubble bag machine is environmentally friendly, which means it can create eco-friendly bubble bags. The machine can create bubble bags that are biodegradable, recyclable, and reusable, which reduces the environmental impact of packaging. The biodegradable bubble bags decompose naturally, reducing the amount of plastic waste in the environment.

Common Types of Air Bubble Bag Machine

Double-layer air bubble bag machines

These machines produce a single layer of bubble wrap and are suitable for smaller-scale production needs.

Three-layer air bubble bag machine

These machines produce a double layer of bubble wrap, providing increased protection for fragile items during shipping.

In addition to the single-layer air bubble film machines and double-layer air bubble film machines, there are other variations available, including 3-layer to 10-layer air bubble film machines. These machines are capable of producing multi-layered bubble wrap with varying degrees of thickness and durability, making them ideal for protecting items during shipping and storage.

High-speed air bubble bag machine

These machines can produce bubble wrap at high speeds, making them ideal for large-scale production needs.

Automatic air bubble bag machine

These machines are fully automated, with features like auto-roll changing and cutting, making them highly efficient and suitable for high-volume production.

How Do You Maintain an Air Bubble Bag Machine

Regular Cleaning: Clean the machine regularly to remove any dust, debris, or adhesive residue that may accumulate during operation. Use a soft cloth and mild detergent to clean the machine gently.

Lubrication: Check the moving parts of the machine regularly and lubricate them as needed to reduce friction and wear. Use lubricants recommended by the manufacturer to ensure compatibility with the machine components.

Inspection: Conduct regular inspections of the machine for any signs of wear, damage, or loose parts. Address any issues promptly to prevent further damage and ensure smooth operation.

Calibration: Calibrate the machine periodically to ensure accurate sealing, cutting, and inflation of air bubbles. Follow the manufacturer's guidelines for calibration procedures and frequency.

Air Compressor Maintenance: If your Air Bubble Bag Machine is equipped with an air compressor, maintain it according to the manufacturer's instructions. Check for leaks, clean filters, and drain moisture from the system regularly.

Training and Operator Care: Provide proper training to operators on how to use the machine correctly and safely. Encourage operators to handle the machine with care and report any issues promptly for timely maintenance.

Record Keeping: Keep detailed records of maintenance activities, repairs, and replacement parts for reference. This information can help track maintenance schedules and troubleshoot issues more effectively.

Features of Air Bubble Bag Machine

Automated Operation

Air bubble bag machines operate automatically, eliminating the need for manual handling.

High Capacity

They have a high production capacity, with some models capable of producing up to 120 bags per minute.

Versatility

The machines can produce air bubble bags in different sizes and shapes to meet the various needs of customers.

Durability

These machines are built with high-quality materials that can withstand high-pressure environments, enhancing their durability and longevity.

Customizable Settings

Air bubble bag machines come with customizable settings that allow you to adjust the production speed, bag length, and other production parameters.

Energy Efficiency

They are designed to minimize energy consumption and reduce production costs.

Easy Maintenance

Air bubble bag machines require minimal maintenance, thanks to their robust construction and simple design.

Safety Features

They have several safety features, such as emergency stop buttons and alarms, that protect operators from accidents.

Air bubble bag offers several benefits. Here are some of them:

Air bubble bag is lightweight

Air bubble bag is very lightweight and easy to carry, use and store.

Air bubble bag can be reused

Air bubble bag can be reused many times as it can be cut into individual pieces. This helps save money because it means you do not have to buy new air bubble bag as often as you would if you were to buy packing paper or other packing materials designed to protect your items.

Air bubble bag is easy to use

When it comes to utilizing the protection capabilities of air bubble bag , its really quite simple. You just wrap your items in air bubble bag and store them wherever they need to be stored for transport. Super easy!

Air bubble bag is durable

Air bubble bag can last for a long time if it is stored properly. This makes it very useful for protecting fragile items for a long time, such as computers, phones, and other electronic devices. It also means that it does not need to be replaced frequently if you are storing something for a long time, which saves money in the long run. Air bubble bag is also more durable than packing paper or foam because it is able to absorb more shock when things are dropped.

Air bubble bag is versatile

Air bubble bag can be cut into small pieces to protect smaller items such as dvds, cds, and even books. It can also be wrapped around small objects such as figurines and statues to keep them safe from damage.

Innovative Uses of Air Bubble Bag Machine in Different Industries

Air bubble bag machines are widely used in various industries for packaging and protecting goods from damage or breakage during transportation. However, with advancements in technology and manufacturing processes, air bubble bag machines have been used in innovative ways to cater to the needs of different industries.

Agriculture Industry - Air bubble bag machines are used to package fresh produce such as fruits and vegetables. The air bubbles act as a cushion and protect the fragile produce from crushing during shipping.

Electronic Industry - Air bubble bag machines are used to package and protect electronic components during transport. The anti-static air bubble bags offer an added layer of protection against electrostatic discharge which can cause damage to electronic devices.

Medical Industry - Air bubble bag machines are used to package medical equipment and supplies such as surgical instruments, diagnostic tools, and medications. Air bubble bags help maintain the sterility of medical equipment and prevent contamination during transit.

Automotive Industry - Air bubble bag machines are used to package auto parts such as engines, transmissions, and other delicate components. The air bubbles provide a cushion that protects these components from damage during shipping.

Retail Industry - Air bubble bag machines are used to package delicate and fragile items sold in retail stores. The air bubbles act as a protective layer that cushions these items and prevents them from breaking or getting damaged during shipping.

Jiangxi Zhetuo Machinery Co., LTD., located in Jinbu Town, Yugan County, Shangrao City, Jiangxi Province, was established in September 2012. Is an annual output value of more than 100 million yuan of packaging machinery technology manufacturing enterprises.

Our Certificate

FAQ

Q: What is the use of air bubble bag?

Q: What are air bubble bags made of?

Q: What is the purpose of bubble wrap?

Q: How do they get air into bubble wrap?

Q: What is an air bubble bag machine?

Q: What are the main parts of an air bubble bag machine?

Q: How does an air bubble bag machine work?

Q: What materials are used to make air bubble bags?

Q: What are the benefits of using air bubble bags?

Q: What are some common applications of air bubble bags?

Q: How do you maintain an air bubble bag machine?

Q: Why do we need a bubble envelope?

Q: Do bubble bags need suffocation warning?

Q: Do the bubbles in bubble wrap go outside?

Q: Do you put bubble wrap on the outside or inside?

Q: Is bubble wrap hazardous?

Q: What gas is in the bubble wrap?

Q: How secure is bubble wrap?

Q: Is bubble wrap air tight?

Q: What is the best way to use bubble wrap?

Hot Tags: air bubble bag machine, China air bubble bag machine manufacturers, suppliers, tea bag making machines, biodegradable plastic bags manufacturing machine, polythene sheet making machine, stretch film wrapper, Heat Insulation Bubble Film Machine, biodegradable plastic machine

You Might Also Like

Send Inquiry