As a seasoned supplier of clothes bag machines, I often encounter inquiries about the production capacity of these machines. Understanding the production capacity is crucial for businesses looking to invest in clothes bag manufacturing equipment, as it directly impacts productivity, efficiency, and overall profitability. In this blog post, I'll delve into the factors that influence the production capacity of a clothes bag machine and provide insights to help you make an informed decision.

Understanding Production Capacity

Production capacity refers to the maximum amount of output a machine can produce within a specific period. For clothes bag machines, this is typically measured in terms of the number of bags produced per hour or per day. However, it's important to note that the actual production capacity can vary depending on several factors, including the type of machine, the material used, the bag size and design, and the operating conditions.

Factors Affecting Production Capacity

1. Machine Type

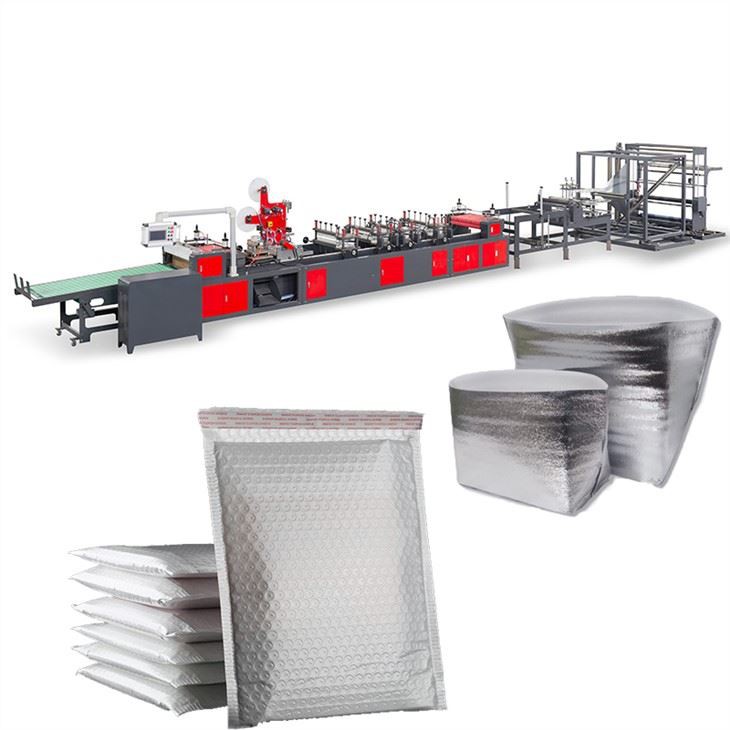

There are various types of clothes bag machines available in the market, each with its own unique features and capabilities. Some of the common types include Side Sealing Bag Making Machine, Bottom Seal Bag Making Machine, and Nonwoven Fabric Sheet Cutting Machine. The production capacity of these machines can vary significantly based on their design and functionality.

For instance, side sealing bag making machines are known for their high-speed production capabilities and can produce a large number of bags per hour. These machines are ideal for mass production of simple bag designs. On the other hand, bottom seal bag making machines are more versatile and can produce bags with different bottom seal configurations, but their production speed may be slightly lower compared to side sealing machines.

2. Material Used

The type of material used to make clothes bags also plays a crucial role in determining the production capacity. Different materials have different physical properties, such as thickness, flexibility, and strength, which can affect the machine's performance. For example, nonwoven fabrics are lightweight and easy to process, allowing for faster production speeds. In contrast, thicker materials like polyethylene or polypropylene may require more time and energy to cut and seal, resulting in a lower production capacity.

3. Bag Size and Design

The size and design of the clothes bags can have a significant impact on the production capacity. Larger bags generally take longer to produce than smaller ones, as they require more material and more time for cutting and sealing. Similarly, bags with complex designs, such as those with handles, zippers, or multiple compartments, may require additional processing steps, which can slow down the production process.

4. Operating Conditions

The operating conditions of the clothes bag machine, such as the temperature, humidity, and power supply, can also affect its production capacity. Machines that are operated in optimal conditions are more likely to perform at their maximum capacity. For example, if the temperature is too high or too low, it can affect the material's properties and the machine's performance. Additionally, a stable power supply is essential to ensure consistent operation and prevent downtime.

Calculating Production Capacity

To calculate the production capacity of a clothes bag machine, you need to consider the following factors:

- Cycle Time: The cycle time is the time it takes for the machine to complete one full cycle of bag production, including cutting, sealing, and any other processing steps. This can be measured in seconds or minutes.

- Number of Cycles per Hour: Once you know the cycle time, you can calculate the number of cycles the machine can complete in one hour by dividing 3,600 (the number of seconds in an hour) by the cycle time.

- Number of Bags per Cycle: The number of bags produced in each cycle depends on the machine's design and the bag size. Some machines can produce multiple bags per cycle, while others produce only one.

- Production Capacity per Hour: To calculate the production capacity per hour, multiply the number of cycles per hour by the number of bags per cycle.

For example, if a clothes bag machine has a cycle time of 5 seconds and can produce 2 bags per cycle, the number of cycles per hour would be 3,600 / 5 = 720 cycles. The production capacity per hour would then be 720 cycles * 2 bags per cycle = 1,440 bags per hour.

Maximizing Production Capacity

To maximize the production capacity of your clothes bag machine, you can take the following steps:

- Choose the Right Machine: Select a machine that is suitable for your production requirements in terms of bag size, design, and material. Consider the machine's speed, efficiency, and reliability.

- Optimize the Operating Conditions: Ensure that the machine is operated in optimal conditions, including the right temperature, humidity, and power supply. Regularly maintain the machine to keep it in good working condition.

- Train Your Operators: Provide proper training to your operators to ensure they are familiar with the machine's operation and can operate it efficiently. Well-trained operators can help reduce downtime and improve productivity.

- Use High-Quality Materials: Using high-quality materials can improve the machine's performance and reduce the likelihood of jams or other issues. Make sure the materials are compatible with the machine and meet your quality standards.

- Implement Lean Manufacturing Principles: Apply lean manufacturing principles to your production process to eliminate waste, reduce lead times, and improve overall efficiency. This can include optimizing the layout of your production facility, streamlining the workflow, and using just-in-time inventory management.

Conclusion

The production capacity of a clothes bag machine is influenced by several factors, including the machine type, material used, bag size and design, and operating conditions. By understanding these factors and taking appropriate measures to maximize production capacity, you can improve the efficiency and profitability of your clothes bag manufacturing business.

If you're interested in learning more about our clothes bag machines or would like to discuss your specific production requirements, please feel free to contact us. We're here to help you find the right solution for your business.

References

- Smith, J. (2020). Introduction to Bag Making Machines. Bag Manufacturing Journal, 15(2), 45-52.

- Johnson, A. (2019). Optimizing Production Capacity in the Textile Industry. Textile Technology Review, 22(3), 67-74.

- Brown, C. (2018). The Impact of Material Properties on Bag Making Machine Performance. Material Science Quarterly, 10(4), 32-39.