The bag edge finishing quality of an HDPE (High-Density Polyethylene) bag making machine is a crucial aspect that significantly impacts the overall quality, functionality, and marketability of the produced bags. As a leading supplier of HDPE bag making machines, we understand the importance of achieving superior bag edge finishing and its implications for our customers' businesses.

Understanding Bag Edge Finishing

Bag edge finishing refers to the process of treating and shaping the edges of HDPE bags during the manufacturing process. This includes tasks such as sealing, trimming, and reinforcing the edges to ensure they are smooth, strong, and aesthetically pleasing. The quality of bag edge finishing can affect several key factors, including:

- Strength and Durability: Well-finished edges enhance the bag's strength and resistance to tearing, ensuring it can withstand the rigors of handling, filling, and transportation.

- Seal Integrity: Properly sealed edges prevent leakage and ensure the contents of the bag remain secure. This is particularly important for bags used to package liquids, powders, or other sensitive materials.

- Aesthetics: Neat and clean edges contribute to the overall appearance of the bag, making it more appealing to consumers. This can enhance brand image and increase the marketability of the product.

- Functionality: Finished edges can improve the ease of use of the bag, such as making it easier to open and close or fold for storage.

Factors Affecting Bag Edge Finishing Quality

Several factors can influence the bag edge finishing quality of an HDPE bag making machine. These include:

- Machine Design and Technology: The design and technology of the bag making machine play a crucial role in determining the quality of the bag edge finishing. Advanced machines are equipped with precision controls, high-quality sealing mechanisms, and cutting tools that can ensure consistent and accurate edge finishing.

- Material Quality: The quality of the HDPE material used in the bag making process can also affect the edge finishing quality. High-quality materials are more likely to produce smooth, strong, and consistent edges, while lower-quality materials may result in uneven or weak edges.

- Operator Skill and Training: The skill and training of the machine operator can have a significant impact on the bag edge finishing quality. Experienced operators are better able to adjust the machine settings, monitor the production process, and troubleshoot any issues that may arise, ensuring optimal edge finishing results.

- Maintenance and Upkeep: Regular maintenance and upkeep of the bag making machine are essential to ensure its continued performance and the quality of the bag edge finishing. This includes cleaning, lubricating, and replacing worn parts as needed.

Our HDPE Bag Making Machines and Bag Edge Finishing Quality

At our company, we are committed to providing our customers with high-quality HDPE bag making machines that deliver superior bag edge finishing results. Our machines are designed and manufactured using the latest technology and highest quality materials, ensuring precision, reliability, and efficiency.

- Advanced Sealing Technology: Our bag making machines are equipped with advanced sealing technology that can ensure strong and consistent seals on the bag edges. This includes hot air sealing, ultrasonic sealing, and impulse sealing, depending on the specific requirements of the application.

- Precision Cutting Tools: We use precision cutting tools to ensure clean and accurate cuts on the bag edges. These tools are designed to minimize burrs and rough edges, resulting in a smooth and professional finish.

- Customizable Settings: Our machines offer customizable settings that allow operators to adjust the sealing and cutting parameters to achieve the desired bag edge finishing quality. This includes temperature, pressure, speed, and other variables, ensuring optimal results for different types of HDPE materials and bag sizes.

- Quality Control Systems: We have implemented strict quality control systems throughout the manufacturing process to ensure that every bag produced meets our high standards of quality. This includes in-line inspection systems that can detect and reject any bags with defective edge finishing, ensuring only the best products are delivered to our customers.

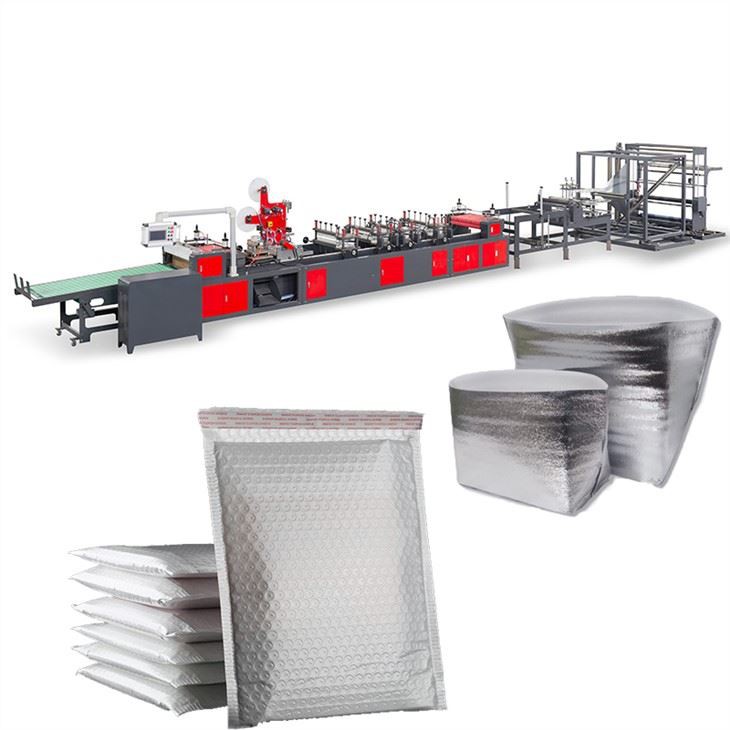

Examples of Our Bag Making Machines

We offer a wide range of HDPE bag making machines to meet the diverse needs of our customers. Some of our popular models include:

- Servo Motor Control Bag Making Machine: This machine features servo motor control technology, which provides precise and accurate control over the bag making process. It is suitable for producing a variety of bag types, including flat bags, side gusseted bags, and bottom gusseted bags.

- Side Sealing Bag Making Machine: This machine is designed specifically for producing side-sealed bags. It uses advanced sealing technology to ensure strong and reliable seals on the side edges of the bag, resulting in high-quality and durable bags.

- Double Line Non Woven T-shirt Bag Making Machine: This machine is capable of producing double-line non-woven T-shirt bags with high efficiency and quality. It features a unique design that allows for the simultaneous production of two bags, increasing productivity and reducing costs.

Importance of Bag Edge Finishing Quality for Your Business

Investing in an HDPE bag making machine with high-quality bag edge finishing capabilities can offer several benefits for your business, including:

- Increased Productivity: High-quality bag edge finishing can reduce the number of defective bags produced, resulting in increased productivity and efficiency. This can save time and money in the long run.

- Improved Product Quality: Well-finished bag edges can enhance the overall quality and appearance of your products, making them more appealing to consumers. This can increase customer satisfaction and loyalty, leading to repeat business and increased sales.

- Enhanced Brand Image: A professional and high-quality appearance can enhance your brand image and reputation in the market. This can differentiate your products from competitors and give you a competitive edge.

- Compliance with Industry Standards: Many industries have specific standards and regulations regarding the quality and safety of packaging materials. Investing in a bag making machine with high-quality bag edge finishing capabilities can help you ensure compliance with these standards and regulations.

Contact Us for Your HDPE Bag Making Machine Needs

If you are looking for a reliable and high-quality HDPE bag making machine with superior bag edge finishing capabilities, look no further. We are a leading supplier of bag making machines, offering a wide range of models to meet your specific needs and requirements.

Our team of experts is available to provide you with detailed information about our products, answer any questions you may have, and assist you in selecting the right machine for your business. We also offer installation, training, and after-sales support services to ensure that you get the most out of your investment.

Contact us today to learn more about our HDPE bag making machines and how they can help you improve the quality and efficiency of your bag production process. We look forward to working with you!

References

- "Plastic Bag Making Technology" by John Smith

- "Advanced Sealing Techniques for Plastic Packaging" by Jane Doe

- "Quality Control in the Plastic Bag Manufacturing Industry" by Tom Johnson