Hey there! As a supplier of handheld shrink wrap machines, I've seen firsthand the amazing benefits these tools bring to various industries. In this blog, I'm gonna share with you all the advantages of using a handheld shrink wrap machine.

Portability and Flexibility

One of the biggest perks of a handheld shrink wrap machine is its portability. Unlike large, stationary shrink wrap systems, you can easily carry a handheld device wherever you need it. Whether you're working in a small workshop, a large warehouse, or even on-site at a customer's location, this machine can go with you. It's like having a super - handy tool that fits right in your hand and can be used on the fly.

This flexibility allows you to shrink wrap products of different sizes and shapes. You're not restricted to a specific conveyor belt or a fixed workspace. For example, if you have irregularly shaped items, like a custom - made piece of furniture or a unique promotional item, a handheld shrink wrap machine can conform to its shape and provide a tight, protective seal.

Cost - Effectiveness

Let's talk about money. Buying a large, industrial shrink wrap machine can be a huge investment. It requires a significant amount of capital upfront, and there are also costs associated with installation, maintenance, and floor space. On the other hand, a handheld shrink wrap machine is much more affordable. It's a great option for small businesses or startups that don't have a lot of money to spend on expensive equipment.

Moreover, since it's a handheld device, you don't need to make major changes to your existing workspace. There's no need to install a complex conveyor system or modify your production line. This saves you both time and money in the long run. You can start using the handheld shrink wrap machine right away without any major disruptions to your business operations.

Ease of Use

Another advantage is how easy these machines are to use. You don't need to be a technical expert to operate a handheld shrink wrap machine. Most models come with simple controls and clear instructions. Even if you're a newbie, you can quickly learn how to use it effectively.

All you usually need to do is load the shrink film onto the machine, position it over the product you want to wrap, and then activate the heat source. The heat will cause the film to shrink and conform to the shape of the product. It's a straightforward process that doesn't require a lot of training or experience.

Quick Setup and Cleanup

Time is money in the business world, and a handheld shrink wrap machine helps you save both. Setting up the machine is a breeze. You can have it up and running in just a few minutes. There's no need for complex assembly or calibration. Once you're done with the shrink - wrapping process, cleaning up is also very easy. You can simply remove any remaining film and store the machine away until the next use.

This quick setup and cleanup time means you can increase your productivity. You can move on to the next task or project without wasting a lot of time on machine preparation and maintenance.

Versatility in Applications

Handheld shrink wrap machines are incredibly versatile. They can be used in a wide range of industries and for various purposes. In the food industry, they're great for wrapping individual food items, like sandwiches, pastries, or cheese blocks. The shrink wrap provides a hygienic barrier that keeps the food fresh and protected from contaminants.

In the retail sector, these machines can be used to wrap promotional items, gift sets, or small electronics. The tight shrink wrap gives the products a professional and attractive look, which can increase their shelf appeal.

In the manufacturing industry, handheld shrink wrap machines can be used to protect parts during shipping and storage. The shrink wrap helps prevent scratches, dust, and moisture from damaging the products.

Compatibility with Different Films

These machines are compatible with a variety of shrink films. You can choose from different types of films based on your specific needs. For example, there are PVC films, which are affordable and offer good clarity. They're great for general - purpose shrink - wrapping applications.

There are also polyethylene films, which are more environmentally friendly and have excellent puncture resistance. If you're dealing with products that are sharp or have rough edges, polyethylene films can provide better protection.

Reduced Waste

Using a handheld shrink wrap machine can help reduce waste. Since you can control the amount of film used more precisely, you're less likely to use excessive amounts of shrink film. This not only saves you money on film costs but also has a positive impact on the environment.

In addition, the shrink wrap can be recycled in many cases. By using a handheld shrink wrap machine, you're making a more sustainable choice for your business.

On - Demand Shrink Wrapping

With a handheld shrink wrap machine, you can perform shrink - wrapping on demand. You don't have to plan your production in advance or batch - process your products. If a customer requests a special order or if you need to quickly wrap a few items for a last - minute shipment, you can do it right away.

This on - demand capability gives you more flexibility in your business operations. You can respond to customer needs more quickly and efficiently, which can improve customer satisfaction and loyalty.

Integration with Other Equipment

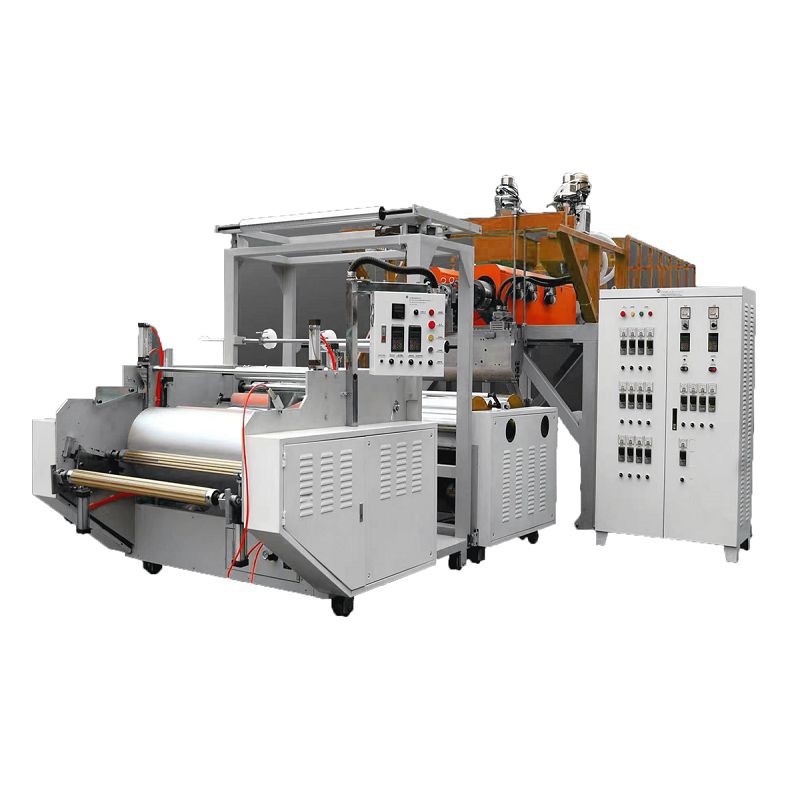

Even though it's a handheld device, a handheld shrink wrap machine can be integrated with other equipment in your production line. For example, you can use it in combination with a Handheld Stretch Wrapper to provide additional protection to your products. The stretch wrapper can hold the products in place while the shrink wrap provides a tight, protective seal.

You can also use it alongside a High Speed Co - extrusion Stretch Film Machine to produce high - quality shrink films in - house. This integration can streamline your production process and improve the overall quality of your shrink - wrapped products.

Safety Features

Most handheld shrink wrap machines come with built - in safety features. These features are designed to protect the user from burns and other injuries. For example, many machines have heat - resistant handles and guards that prevent accidental contact with the hot parts of the machine.

Some machines also have automatic shut - off functions. If the machine overheats or if there's a problem with the electrical system, it will automatically turn off to prevent any damage or safety hazards.

If you're looking for a reliable and efficient way to shrink wrap your products, a handheld shrink wrap machine is the way to go. It offers so many advantages in terms of portability, cost - effectiveness, ease of use, and versatility. Whether you're a small business owner or a large - scale manufacturer, these machines can meet your shrink - wrapping needs.

If you're interested in learning more about our handheld shrink wrap machines or if you want to discuss your specific requirements, don't hesitate to get in touch. We're here to help you find the perfect solution for your business.

References

- Industry reports on shrink wrap technology

- Manufacturer's manuals for handheld shrink wrap machines

- Case studies of businesses using handheld shrink wrap machines