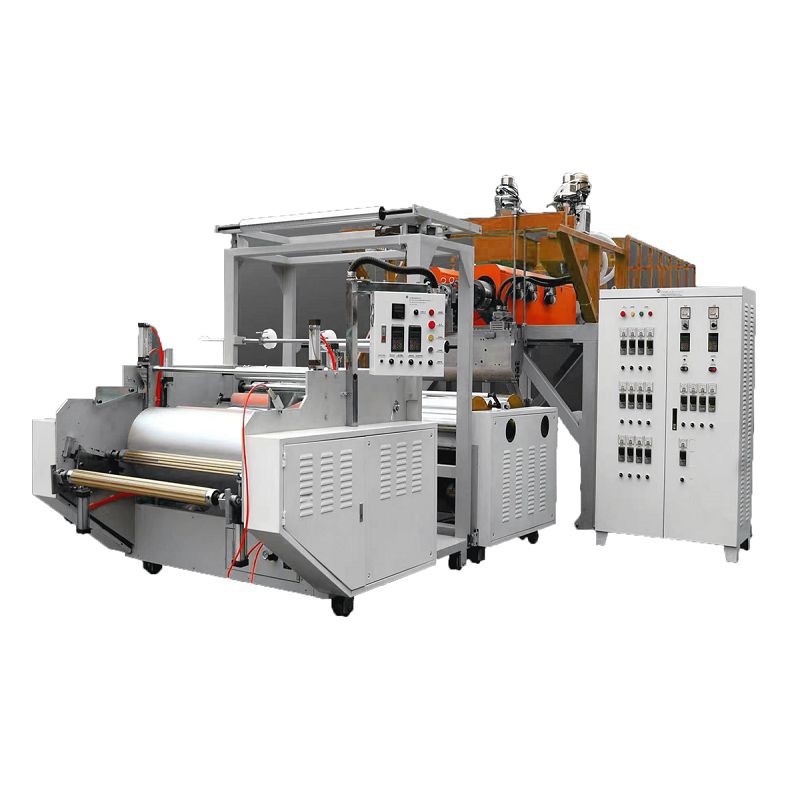

In the dynamic landscape of modern packaging, the Highlight Stretch Wrap Machine has emerged as a pivotal tool for businesses aiming to streamline their packaging processes. As a leading supplier of this innovative machinery, I often encounter a common question from potential clients: "Does the Highlight Stretch Wrap Machine have a self - diagnostic function?" This blog post aims to delve into this question, providing a comprehensive understanding of the self - diagnostic capabilities of our Highlight Stretch Wrap Machine.

The Importance of Self - Diagnostic Function in Packaging Machines

Before we explore the self - diagnostic features of the Highlight Stretch Wrap Machine, it's essential to understand why such a function is crucial in the packaging industry. Packaging machines are complex pieces of equipment that operate under various conditions and handle different types of products. Any malfunction or inefficiency can lead to production delays, increased costs, and compromised product quality.

A self - diagnostic function allows the machine to monitor its own performance continuously. It can detect potential issues early, such as mechanical wear, electrical faults, or software glitches. By identifying problems at an early stage, operators can take proactive measures to address them, minimizing downtime and reducing the risk of costly breakdowns. Moreover, self - diagnostic systems can provide detailed reports on the machine's status, enabling maintenance teams to perform targeted repairs and optimize the machine's operation.

Self - Diagnostic Capabilities of the Highlight Stretch Wrap Machine

Our Highlight Stretch Wrap Machine is equipped with a state - of - the - art self - diagnostic system that offers a wide range of features designed to ensure optimal performance and reliability.

Real - Time Monitoring

The self - diagnostic system continuously monitors various parameters of the machine, including motor speed, film tension, and wrapping cycle time. By collecting real - time data, the system can detect any deviations from the normal operating range. For example, if the film tension is too high or too low, the system will immediately alert the operator, allowing them to adjust the settings and prevent potential issues such as film breakage or improper wrapping.

Fault Detection and Notification

In addition to real - time monitoring, the self - diagnostic system can detect specific faults within the machine. It uses advanced algorithms to analyze the data collected from sensors and other components, identifying potential problems such as sensor malfunctions, electrical shorts, or mechanical jams. When a fault is detected, the system will display a detailed error message on the machine's control panel, indicating the nature of the problem and suggesting possible solutions. Some errors can also be sent directly to the operator's mobile device via SMS or email, ensuring that they are notified immediately, even if they are not on - site.

Predictive Maintenance

One of the most significant advantages of the self - diagnostic system in the Highlight Stretch Wrap Machine is its ability to perform predictive maintenance. By analyzing historical data and trends, the system can predict when certain components are likely to fail or require maintenance. For example, it can estimate the remaining lifespan of a motor or a bearing based on its usage and operating conditions. This allows maintenance teams to schedule preventive maintenance tasks in advance, reducing the risk of unexpected breakdowns and extending the machine's overall lifespan.

Remote Monitoring and Support

Our Highlight Stretch Wrap Machine also supports remote monitoring and support. Through a secure internet connection, our technical support team can access the machine's self - diagnostic system remotely, allowing them to diagnose and troubleshoot problems without the need for an on - site visit. This not only saves time and money but also ensures that the machine is back up and running as quickly as possible. Additionally, remote monitoring enables us to provide proactive support, such as software updates and performance optimization, to keep the machine operating at its best.

Comparison with Other Stretch Wrap Machines

When compared to other stretch wrap machines on the market, the self - diagnostic function of our Highlight Stretch Wrap Machine offers several distinct advantages.

Many traditional stretch wrap machines lack advanced self - diagnostic capabilities, relying instead on manual inspections and periodic maintenance. This approach can be time - consuming and may not detect potential issues until they have already caused significant problems. In contrast, our Highlight Stretch Wrap Machine's self - diagnostic system provides continuous monitoring and early detection, allowing for proactive maintenance and minimizing the risk of downtime.

Some competing machines may have basic self - diagnostic features, but they often lack the sophistication and comprehensiveness of our system. Our system's ability to perform predictive maintenance and support remote monitoring sets it apart from the competition, providing our customers with a higher level of reliability and support.

Applications and Benefits for Different Industries

The Highlight Stretch Wrap Machine with its self - diagnostic function is suitable for a wide range of industries, each benefiting from its unique capabilities.

Manufacturing

In the manufacturing industry, where production efficiency is crucial, the self - diagnostic function of the Highlight Stretch Wrap Machine can help minimize downtime and ensure consistent product quality. By detecting and addressing potential issues early, manufacturers can avoid costly production delays and maintain a smooth production flow. For example, in an automotive manufacturing plant, the machine can be used to wrap pallets of auto parts, and the self - diagnostic system can ensure that the wrapping process is always reliable, protecting the parts during transportation and storage.

Logistics and Warehousing

Logistics and warehousing companies often deal with a large volume of products that need to be wrapped and stored efficiently. The self - diagnostic function of the Highlight Stretch Wrap Machine can help these companies optimize their operations by reducing the time and resources spent on maintenance. With real - time monitoring and fault detection, operators can quickly identify and resolve any issues, ensuring that the pallets are wrapped securely and ready for shipping. This can improve the overall efficiency of the supply chain and reduce the risk of product damage during transit.

Food and Beverage

In the food and beverage industry, product safety and hygiene are of utmost importance. The Highlight Stretch Wrap Machine's self - diagnostic system can help ensure that the wrapping process meets the strictest standards. By monitoring the machine's performance and detecting any potential contamination or malfunction, the system can prevent product spoilage and ensure that the food and beverages are properly protected. For example, in a dairy processing plant, the machine can be used to wrap milk cartons, and the self - diagnostic system can ensure that the wrapping is tight and secure, preventing leaks and maintaining product freshness.

Conclusion and Call to Action

In conclusion, the Highlight Stretch Wrap Machine's self - diagnostic function is a game - changer in the packaging industry. It offers real - time monitoring, fault detection, predictive maintenance, and remote support, providing our customers with a reliable and efficient packaging solution. Whether you are in the manufacturing, logistics, or food and beverage industry, our machine can help you streamline your operations, reduce costs, and improve product quality.

If you are interested in learning more about our Highlight Stretch Wrap Machine or other packaging solutions such as the Automatic Shrink Wrap Machine For Pallets and the High Speed 5 Layer Stretch Film Machine, please do not hesitate to contact us. Our team of experts is ready to assist you in finding the perfect packaging solution for your business needs. Let's start a conversation and explore how our machinery can enhance your packaging processes.

References

- Packaging Machinery Manufacturers Institute (PMMI). "The Importance of Self - Diagnostic Systems in Packaging Equipment."

- Industry research reports on stretch wrap machines and their applications in different industries.

- Technical documentation of the Highlight Stretch Wrap Machine.