Can machine stretch film be used for wrapping food products? This is a question that often comes up among businesses and consumers alike. As a supplier of machine stretch film, I am frequently asked about the suitability of our products for food packaging. In this blog post, I will explore the factors that determine whether machine stretch film can be used for wrapping food, the types of stretch film that are safe for food contact, and the benefits of using machine stretch film for food packaging.

Factors to Consider

When determining whether machine stretch film can be used for wrapping food, several factors need to be considered. These include the type of food being wrapped, the intended use of the packaging, and the regulatory requirements in the target market.

Type of Food

The type of food being wrapped is a crucial factor in determining the suitability of machine stretch film. Different foods have different characteristics, such as moisture content, acidity, and fat content, which can interact with the stretch film and affect its performance. For example, fatty foods may require a stretch film with a higher resistance to grease and oil, while high-moisture foods may need a film with good moisture barrier properties.

Intended Use

The intended use of the packaging also plays a significant role in determining the suitability of machine stretch film. If the food is going to be stored at room temperature for a short period, a standard stretch film may be sufficient. However, if the food needs to be refrigerated or frozen, a stretch film with better temperature resistance and durability may be required. Additionally, if the food is going to be cooked or heated in the packaging, the stretch film must be able to withstand the high temperatures without melting or releasing harmful chemicals.

Regulatory Requirements

Regulatory requirements vary from country to country and can have a significant impact on the use of machine stretch film for food packaging. In many countries, there are strict regulations regarding the materials that can be used in direct contact with food. These regulations typically specify the types of polymers, additives, and processing aids that are allowed, as well as the maximum levels of migration of these substances into the food. It is essential to ensure that the stretch film used for food packaging complies with all relevant regulatory requirements.

Types of Machine Stretch Film for Food Packaging

There are several types of machine stretch film that are suitable for food packaging. These include polyethylene (PE) stretch film, polyvinyl chloride (PVC) stretch film, and ethylene-vinyl acetate (EVA) stretch film.

Polyethylene (PE) Stretch Film

Polyethylene is the most commonly used polymer for food packaging due to its excellent clarity, flexibility, and moisture barrier properties. PE stretch film is available in different grades, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). LDPE and LLDPE are the most commonly used grades for food packaging because they are soft, flexible, and have good cling properties. HDPE is less commonly used for food packaging because it is stiffer and has a lower cling force.

Polyvinyl Chloride (PVC) Stretch Film

PVC stretch film is another popular choice for food packaging, especially for fresh produce and meat. PVC stretch film has excellent clarity, high gloss, and good cling properties. It also has good resistance to moisture, oxygen, and odor, which helps to preserve the freshness and quality of the food. However, PVC stretch film contains plasticizers, which are chemicals that are added to make the film more flexible. Some plasticizers, such as phthalates, have been linked to health problems, so it is important to use PVC stretch film that is compliant with food safety regulations.

Ethylene-Vinyl Acetate (EVA) Stretch Film

EVA stretch film is a copolymer of ethylene and vinyl acetate. It has excellent flexibility, clarity, and cling properties, as well as good resistance to moisture and oxygen. EVA stretch film is often used for wrapping delicate foods, such as fruits and vegetables, because it is gentle on the surface of the food and does not damage it.

Benefits of Using Machine Stretch Film for Food Packaging

There are several benefits of using machine stretch film for food packaging. These include:

Protection

Machine stretch film provides a protective barrier against moisture, oxygen, and other contaminants, which helps to preserve the freshness and quality of the food. It also helps to prevent the food from drying out, spoiling, or being damaged during storage and transportation.

Convenience

Machine stretch film is easy to use and can be applied quickly and efficiently using a stretch wrapping machine. This saves time and labor costs compared to manual wrapping methods. Additionally, machine stretch film can be customized to fit the specific needs of the food product, such as size, shape, and thickness.

Cost-Effectiveness

Machine stretch film is a cost-effective packaging solution compared to other types of packaging materials, such as glass, metal, and paper. It is also lightweight, which reduces shipping costs and carbon emissions.

Sustainability

Many machine stretch films are made from recyclable materials, which makes them a more sustainable packaging option compared to non-recyclable materials. Additionally, machine stretch film can be used to reduce food waste by extending the shelf life of the food and preventing it from spoiling.

Our Machine Stretch Film Products for Food Packaging

As a supplier of machine stretch film, we offer a wide range of products that are suitable for food packaging. Our products are made from high-quality materials and are designed to meet the specific needs of our customers. Some of our popular products include:

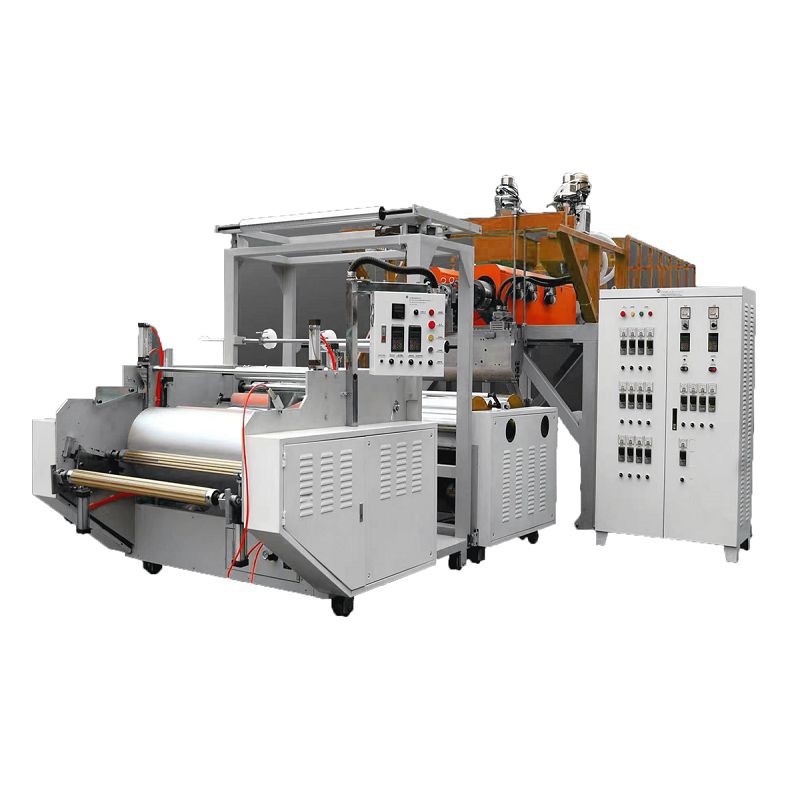

High Speed 5 Layer Stretch Film Machine

This machine is designed to produce high-quality 5-layer stretch film with excellent clarity, strength, and stretchability. The 5-layer structure provides better performance and durability compared to traditional single-layer or 3-layer stretch film.

Highlight Stretch Wrap Machine

This machine is ideal for wrapping food products of various shapes and sizes. It uses a unique highlighting technology to ensure that the stretch film is applied evenly and tightly around the food product, providing maximum protection and stability.

Industrial Stretch Wrap Machine

This machine is designed for high-volume production and is suitable for wrapping large quantities of food products. It has a high-speed wrapping capability and can handle a wide range of film thicknesses and widths.

Conclusion

In conclusion, machine stretch film can be used for wrapping food products, but it is important to choose the right type of film and ensure that it complies with all relevant regulatory requirements. Polyethylene, polyvinyl chloride, and ethylene-vinyl acetate are some of the most commonly used polymers for food packaging, each with its own unique properties and benefits. Machine stretch film provides several advantages, including protection, convenience, cost-effectiveness, and sustainability. As a supplier of machine stretch film, we offer a wide range of products that are suitable for food packaging and can help you meet your specific needs. If you are interested in learning more about our products or would like to discuss your packaging requirements, please contact us for a consultation.

References

- European Food Safety Authority. (2019). Scientific opinion on the safety assessment of polyethylene (PE) as a food contact material. EFSA Journal, 17(9), e05839.

- Food and Drug Administration. (2021). Food contact substances notified to FDA. Retrieved from https://www.fda.gov/food/food-contact-substances/food-contact-substances-notified-fda

- International Organization for Standardization. (2019). Packaging - Flexible plastic films for food packaging - Determination of oxygen transmission rate - Part 1: Amperometric sensor method. ISO 15105-1:2019.